Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Stamping

Stamping is a versatile and innovative tool that allows you to add a touch of elegance and personalization to any project. Whether you are a seasoned crafter or just starting out, this incredible stamping set will take your creativity to new heights.

During sheet metal stamping, a press feeds metal into a die, shaping it with immense force, measured in tons. Unlike some specialized processes, sheet metal stamping is typically conducted without heat, utilizing a cold-forming technique. Despite the absence of heat, the part may emerge hot due to the friction generated between the metal and the die from the press force.

Stamping Materials

Though virtually any metal, including gold, can be stamped, sheet metal is by far the most common. The type of metal used depends on the type of part that’s needed and its desired properties, such as corrosion- and heat-resistance.

Stamping can produce parts from the following materials:

- Stainless steel

- Low- and high-carbon steel

- Aluminum

- Titanium

- Brass

- Bronze

- Copper

- Inconel

- Nickel alloys

Finishing Options for Stamping

Improve the surfaces of your stamping parts and finished products with outstanding surface finishing options. Future Parts offers various finishes to enhance the product’s aesthetic look and other properties.

|

Name |

Decsription |

Materials |

Color |

Texture |

|

Anodizing |

Anodizing improves corrosion |

Aluminum |

Clear, black, grey, |

Smooth, |

|

Bead Blasting |

Bead blasting results in parts |

ABS, Aluminum, |

N/A |

Matte |

|

Powder Coating |

Powder coating is a type of |

Aluminum, |

Black, RAL code |

Gloss or |

|

Electroplating |

Electroplating can be functional, |

Aluminum, steel, |

N/A |

Smooth, glossy |

|

Polishing |

Polishing is the process of |

Aluminum, Brass, |

N/A |

Glossy |

|

Brushing |

Brushing is a surface treatment |

ABS, Aluminum, |

N/A |

Satin |

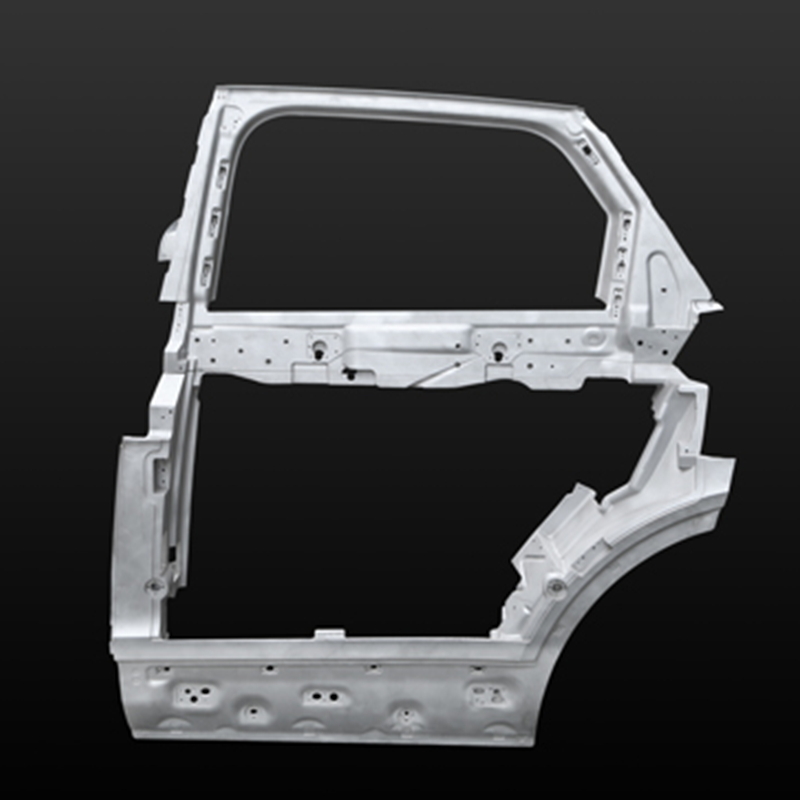

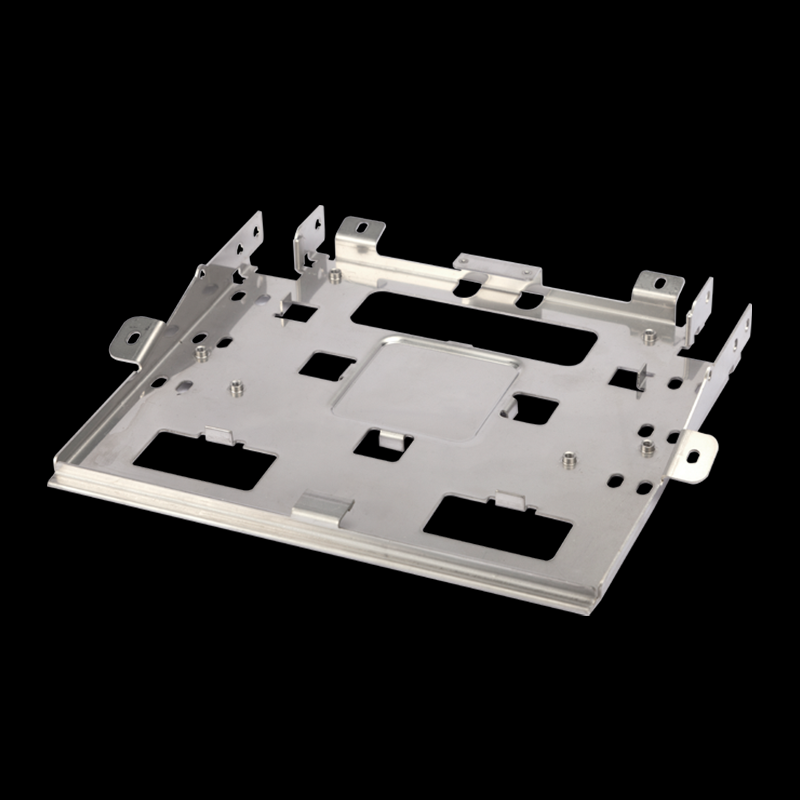

The Application of product

In the stamping process, metal is transformed into complex parts using highly specialized computer-aided drafting and manufacturing programs. Stamping produces superior, resilient, heavy-duty parts quickly and efficiently. The results are so precise, they’re typically more reliable and consistent than manual machining.

The following industries use components that are created via stamping:

- Automotive

- Renewable energy

- Medical

- Industrial

- Hardware

- Home Improvement

This list is by no means exhaustive. There is a considerable demand for sheet metal stamping, and the range of industries that depend on it is vast.

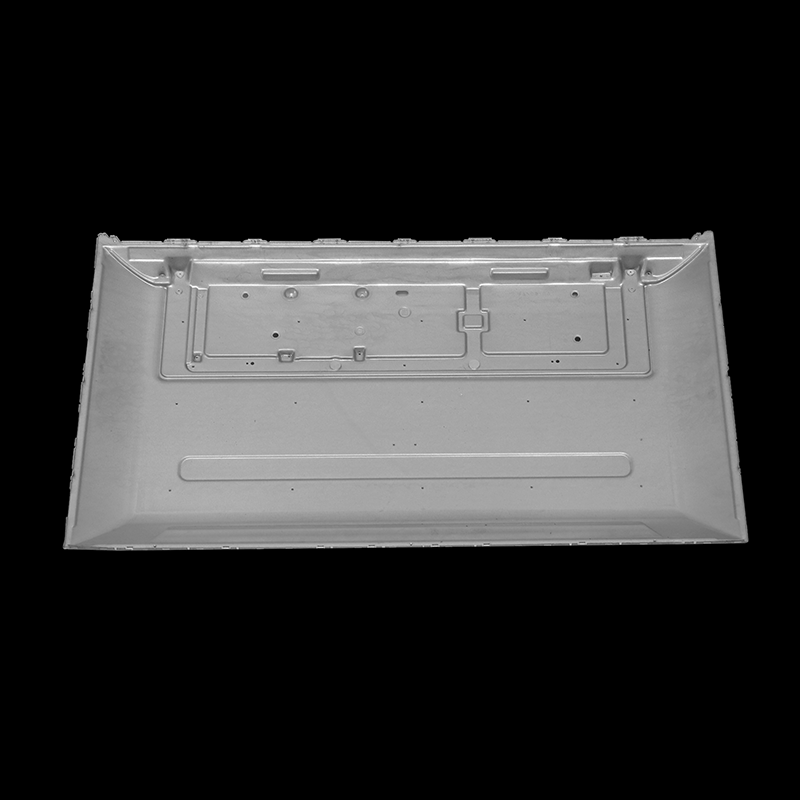

The Production Process of product

Metal stamping involves three key components: metal, die, and press machine. Despite the simplicity of these elements, the process often requires multiple steps to achieve the final part. Here's a brief guide to some common metal stamping processes:

Forming:

- Transformation of metal into various shapes by applying force.

- Multiple operations can convert simple shapes into complex ones.

Blanking:

- Basic technique where the die cuts the material to create a shape called a blank.

- The blank can be the final part (fully finished blank) or proceed to the forming step.

Drawing:

- Involves carefully drawing material into a cavity to create vessels or deep depressions.

- Tension is applied, minimizing material stretching.

- Used in crafting sinks, cooking equipment, and vehicle oil pans.

Piercing:

- Opposite of blanking; material around the punched area is utilized.

- Similar to cutting biscuits from rolled-out dough, where the cutouts are discarded, and the hole-riddled remains are the desired outcome.

Why Choose Us?

Outstanding stamping services for high-quality custom prototypes and production parts. Achieve the best possible bending results at low cost and fast turnarounds.

Free quotation with DFM review within 1 day

Lead time as fast as 3-5 days