Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

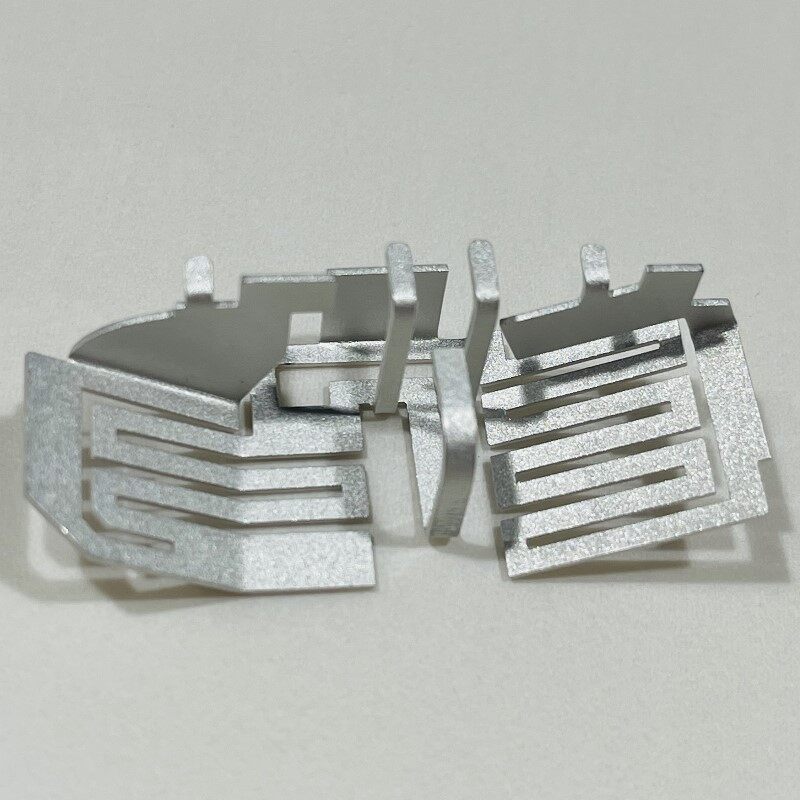

Laser Cutting Service

Backed by outstanding manufacturing capabilities and 15+ years of industry experience, Future Parts offers superior quality custom laser cutting services. Equipped with highly skilled machinists and cutting-edge laser cutting facilitie, we are able to cut anything from delicate aluminum foils to thick steel sheets. Get custom high-precision sheet metal prototypes and parts with an extensive range of advanced processes and technology.

The description of product

- Fiber Laser Cutting

With outstanding precision results, fiber laser cutting produces excellent results on materials with less than 20mm thickness. This process can help achieve even complex cutting operations like engraving and annealing.

- CO2 Laser Cutting

Take advantage of the highly advanced combination of electricity and gases to cut non-metal components like plastics, acrylics, and wood. This laser cutting process also gives excellent results with thin sheets of aluminum and other non-ferrous metals

- Nd:Yag Laser Cutting

This high-power laser cutting process offers an even more advanced online laser cutting service for coated and uncoated metals, plastic, and other non-metals. Enjoy top-notch laser cutting parts with increased life expectancy and the best quality.

Laser Cutting Standards

Future Parts follows international industry standards and market trends to offer premium laser cutting parts to our customers. We have state-of-the-art laser cutting machines that offer the finest and most precise cutting. These technologies allow us to cut at higher speed, with versatile design change, narrow kerf, burr-free edges and holes, and less material waste, all at reduced costs.

Specification

|

Standards |

Description |

|

Minimum part size |

10 mm (0.40 in.) |

|

Minimum feature size |

2X material thickness with a minimum of 1 mm (0.04 in.) |

|

Distance dimensions |

Standards depend on ISO 2768-c. Typical size: +/- 0.2 mm (0.008 in.) for length, width, diameter and location. |

|

Maximum material thickness |

Carbon steel < 25 mm (0.98 in.) Stainless steel < 15 mm (0.59 in.) Aluminum < 15 mm (0.59 in.) Copper < 12.7 mm (0.5 in.) |

|

Kerf (slit size) |

About 0.5 mm (0.02 in.) |

|

Edge condition |

Laser cut edges have matte and vertical lines. |

|

Laser sources |

CO2 and fiber lasers. Up to 10 kW. |

|

Repeatability |

±0.05 mm (0.002 in.) |

|

Repeatability |

±0.10 mm (0.004 in.) |

|

Lead Time |

5-7 days |

Laser Cutting Materials

Future Parts’s laser cutting service is versatile and compatible with various materials, ranging from ferrous to non-ferrous metals, plastics, and other non-metals. Our laser cutting facility combines ultra-modern technology with skilled professionals to laser cut materials across different strengths, weights, and thermal properties. Here are some laser cutting materials available for your project.

Metal: Aluminum, Stainless steel, Steel, Copper

Plastic: Acrylic, PMMA, Delrin (POM, Acetal), Polyethylene, Polypropylene, Styrene, Lucite, Mylar (polyester)

Finishing Options for Laser Cutting

Choose from the extensive list of finishing options to improve the surfaces of your custom laser cut parts and products to improve their cosmetic appearance, corrosion resistance, and durability.

|

Name |

Decsription |

Materials |

Color |

Texture |

|

Anodizing |

Anodizing improves corrosion |

Aluminum |

Clear, black, grey, |

Smooth, |

|

Bead Blasting |

Bead blasting results in parts |

ABS, Aluminum, |

N/A |

Matte |

|

Powder Coating |

Powder coating is a type of |

Aluminum, |

Black, RAL code |

Gloss or |

|

Electroplating |

Electroplating can be functional, |

Aluminum, steel, |

N/A |

Smooth, glossy |

|

Polishing |

Polishing is the process of |

Aluminum, Brass, |

N/A |

Glossy |

|

Brushing |

Brushing is a surface treatment |

ABS, Aluminum, |

N/A |

Satin |

The Advantage of product

Laser cutting offers several benefits for many industries, ranging from precision, speed, repeatability, and flexibility. Future Parts’s laser cutting service help meet industry requirements in terms of functionality and aesthetics.

- High Precision Cuts: The light beam involved in laser cutting ensures high-precision melting and evaporation of materials, ensuring accuracy as low as 0.003mm.

- Maximum Sheet Utilization: The laser cutting technology maximizes the number of usable metal sheets and gives little room for wastage, ensuring that only the exact amount of material is provided.

- High Cutting Versatility: With advanced laser cutting operations, you can get custom laser cut parts with simple cuts, marking, engravings, and complex, intricate details.

- Low Power Use: Sheet metal laser cutters effectively cut out material pieces without consuming too much energy, often using just 10kW of energy.

- Little to No Damage: The heat from laser cutting processes affects very minimal areas on the component and has no effect on the tolerance of the laser cutting parts.

The Application of product

Many industries worldwide are gradually transitioning to laser cutting technology because it provides additional benefits such as precision, tight tolerance, flexibility, clean finish, enhanced productivity, and design complexity. For prototype or full-scale manufacturing, switching to laser cutting will help saving time and money.

- Aerospace

The laser cutting technology helps to cut aluminum, stainless steel, and titanium for aerospace engineering. Intricate pieces, high-strength aluminum alloys, and various rare metals are cut with a low HAZ and tight tolerance with the help of the laser cutting process.

- Automotive

Precision laser cutting allows for the assembly of complex automotive pieces. Laser metal cutting tools can accurately process automotive parts such as brakes, exhaust pipes, doors, etc. Part and serial numbers can also be engraved on produced items.

- Medical Devices

Laser cut parts are used in the medical sector to produce everything from beds and trolleys to diagnostic equipment, orthopedic rods, aluminum brackets, and surgical tools. Precision laser cutting creates flexible shafts, vascular clips, bone reamers, valve frames, hones, etc.

- Electronic Components

The capacity of laser technology to cut intricate components, swiftly switch between different materials and cause little heat damage to the surrounding region are the key reasons for its extensive usage in this sector. Some applications include multi-layer circuit boards, polished metal gadget enclosures, and micro SD cards.

- Kitchware

Laser cutting equipment is capable of generating very detailed designs, making them suitable for crafting ornamental objects like vases and bowls, helping you get the style wanted, from simple borders to complex designs on pots and pans.

- New Energy Industry

Laser cutting technologies are used in the new energy industry to accurately cut solar cells and thin film materials, reducing waste and increasing efficiency. The laser cutting process also helps with the clean and precision cutting of lithium-ion batteries, which is critical for maintaining the batteries’ optimal performance.