Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Vacuum Casting

Vacuum casting, also known as urethane casting, blends silicone molds and 3D printed master patterns to produce short-run, rigid parts with production-level precision. Utilizing thermoplastic polyurethane within silicon or epoxy molds, the process replicates the shapes of the original master models. Final dimensions depend on the master model, part geometry, and chosen materials.

As a leading vacuum casting manufacturer, Future Parts provides cost-effective fabrication of high-quality plastic components, eliminating the need for substantial upfront investments. Our vacuum casting services present a comprehensive solution for crafting top-tier prototypes and low-volume production parts, particularly when aesthetic considerations are paramount.

Our Vacuum (Urethane) Casting Services

Vacuum casting sometimes referred to as Urethane casting or Polyurethane casting, is a perfect solution for production quality parts without the cost or lead time required for production tooling. At Future Parts, we have a massive range of plastic materials available, and we can cast parts as large and small, everything from headphones all the way up to 2m long car bumpers.

Vacuum Casting Materials

|

Material

|

Picture

|

Description

|

Material Reference

|

Appearance

|

|

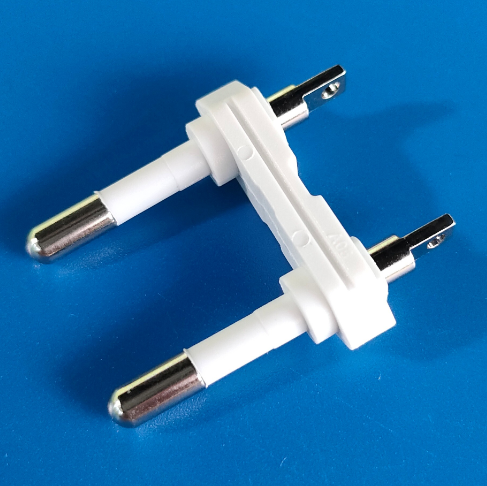

Soft-rubber-like

|

|

Vacuum casting is excellent choice for creating

rubber parts and prototypes. Soft-rubber-like

materials are useful in applications that demand

flexibility and durability for industrial parts and

consumer goods alike.

|

T0387,8400

|

Colorless Transparent,

Yellow Transparent

|

|

PA-like

|

|

PX223, a PA-like material, is used in silicone

molds for the production of parts that are highly

durable and versatile with properties similar to

nylon parts.

|

PX223

|

Black, Tawny

|

|

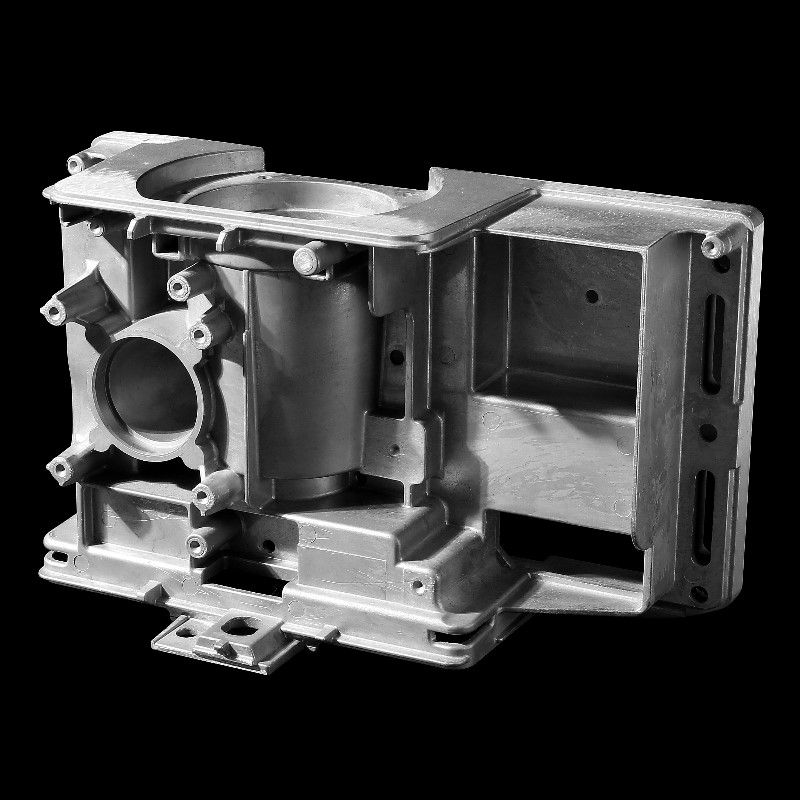

ABS-like

|

|

With vacuum casting, you can create high rigid

ABS-like parts with good impact resistance and

insulating properties. They are commonly used to

make electronic housings, automotive parts and

more.

|

Hei-Cast 8150, PZ858,

6160, P+600

|

Beige, Black, Milky

white

|

|

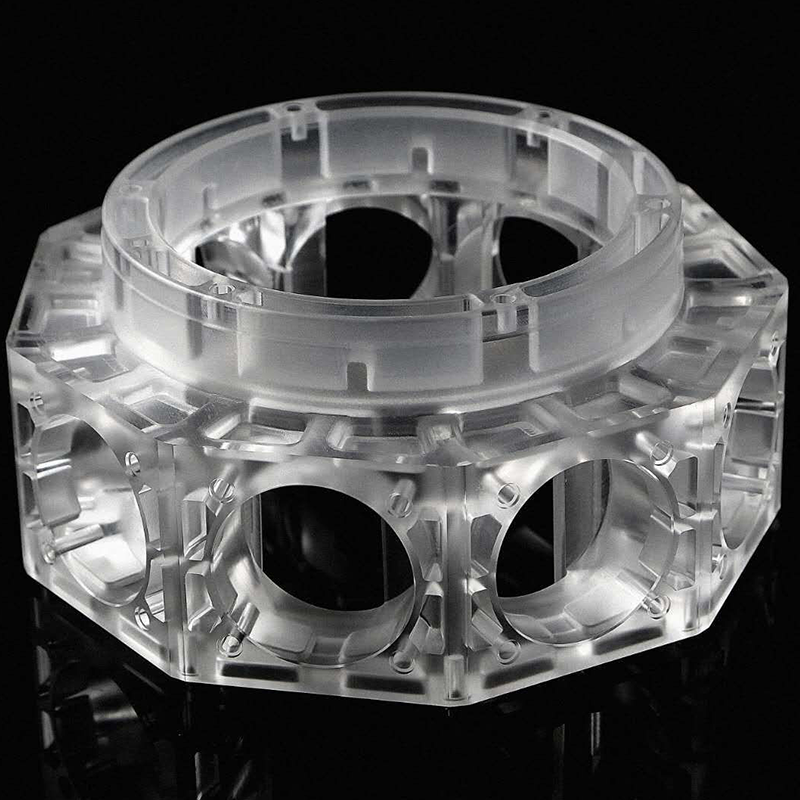

PMMA-like

|

|

Urethane casting is a great choice for creating

clear transparent parts. While inferior to true

PMMA, PX-5210 has good transparency, is easy

to polish, resistant to yellowing, and offers good

UV resistance. This makes it suitable for a wide

range of applications where clear parts are

needed.

|

PX 5210

|

Transparent

|

|

PP-like

|

|

UP 5690 have mechanical properties similar to

that of true PP and HDPE material. It is easy to

process, has high impact resistance and good

flexibility, and can be used for bumpers,

equipment boxes, covers and anti-vibrant tools.

|

UP 5690

|

White, Black

|

|

PC-like

|

|

PX520 is used by casting in silicone moulds for

the realization of prototype parts and mock-ups

with mechanical properties similar to that of true

PC material.

|

PX520

|

White, Clear

|

Vacuum Casting Tolerances

Future Parts offers a range of vacuum casting tolerances to meet your custom requirements. Based on the master pattern and part geometry, we can reach dimensional tolerances between 0.2 – 0.4 m. Below are the technical specifications for our vacuum casting services.

| Type | Information |

| Accuracy | Highest precision to reach +0.05 mm |

| Max Part Size | +/- 0.025 mm +/- 0.001 inch |

| Minimum wall thickness | 1.5mm~ 2.5mm |

| Quantities | 20-25 copies per mold |

| Color & Finishing | Color and texture can be customized |

| Typical Lead Time | Up to 20 parts in 15 days or less |

The Advantage of product

- Vacuum Casting vs Plastic Injection Moulding

Vacuum casting produces parts with similar properties to plastic injection moulded parts. Injection moulding demands a higher front-end cost and a lower unit price, whereas vacuum casting offers a lower front-end cost with a higher unit price. This makes urethane casting a more cost-effective choice for developing early prototypes before creating end-use injection moulded parts.

- Vacuum Casting is Used For

Low volume prototypes, low volume production, clear transparent parts, rubber parts, market testing, rapid iterations

Advantages of Vacuum Casting

- Great for low volumes

- Self-coloured parts

- Low upfront investment

- Production like parts

- Massive range of materials

The Feature of product

| Applicable Materials | Colors | Decsription | |

| Painting | All | Black, Pantone/RAL colours | Painting is a way to add colour, a great way to improve the aesthetics of vacuum casted parts. |

| Plating | All | Metallic | Plating is method of adding a thin layer of metal of the outer layer of a material. It is used to harden,decorate and improve wearability of parts. |

The Application of product

The advantages of vacuum casting have made it a choice for many applications across different industrial sectors, including:

- Robotics

- Automotive

- consumer goods

- Technology

- medical & pharmaceutical

- toys

The Production Process of product

The vacuum casting process involves three main stages.

1.Building a master model using 3D printing (via SLA or SLS) or CNC machining.

2.Building the silicone tool by pouring liquid silicone around the master model then curing it.

3.The resin is poured into the cavity to create a production-like replica.