Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

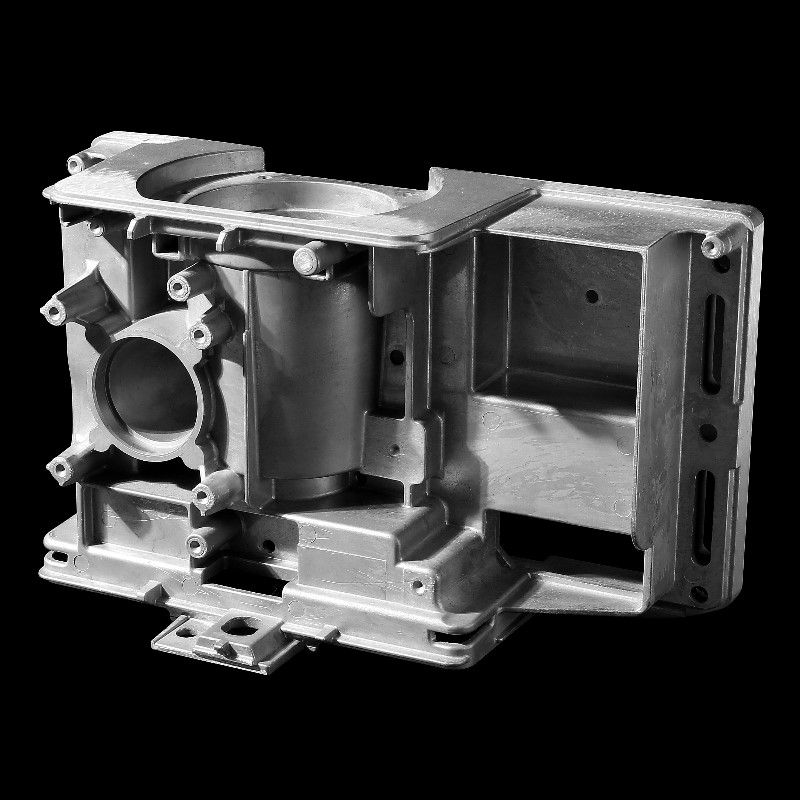

Overmolding

The overmolding process involves molding one plastic material over another. This ensures a seamless combination of multiple plastic parts to give a uniform and durable product. Insert molding and multi-shot molding processes help combine materials for functional and aesthetic purposes. Future Parts’s plastic injection overmolding uses these processes to ensure every component meets industrial standards.

Custom Overmolding Services

- Improved Design and Creation of Custom Plastic Parts: Overmolding capabilities ensure the creation of custom plastic-plastic or metal-plastic product combinations with a high dimensional quality.

- Better Product Performance: Overmolded parts are of excellent quality because of their two-material advantage for various applications.

- Increased Shelf and Aesthetic Appeal: The overmolding process can be optimized with many materials and surface treatment processes to improve the aesthetic quality of the product.

- Better Shock Absorption and Overall Durability: Overmolding also offers improved shock absorption due to the plastic resin addition, ensuring longer shelf life and excellent resistance against impacts.

- Lower Production Costs: Since overmolding eliminates post-assembly phase of production, it speeds up the production process and reduces overall manufacturing cost.

Future Parts Overmolding Capabilities

Future Parts’s custom overmolding services ensure the creation of plastic parts that look and perform better. Our production line consists of an overmolding injection molding process that allows us to combine several different materials into one, ensuring you get superior-quality products.

Specification

|

Standards |

Metric Units |

Imperial Units |

|

Maximum Part Size |

200×400×100mm |

7.87×15.75×3.94in |

|

Minimum Part Size |

2×2×2mm |

0.08×0.08×0.08in |

|

Substrate Wall Thickness |

0.5~3 mm |

0.20~0.12 in |

|

Tolerance |

±0.025mm |

±0.00098 in |

|

Radii |

0.1mm |

0.0039in |

|

Depth |

100mm from the parting line |

3.94in. from the parting line |

|

Mold Validation |

Provide T0, T1, T2 samples before mass production |

|

|

Inspection and Certifiaction |

First Article Inspection, ISO 9001, ISO 13485 |

|

|

Lead Time |

From mold making to sample delivery: 15-45 business days |

|

Materials for Overmolding

Future Parts’s overmolding service incorporates choosing the right materials, ranging from thermoplastics to exotic resins. There are multiple possible combinations of overmolding materials and substrates. Here are some of the most common materials we use for the plastic overmolding process.

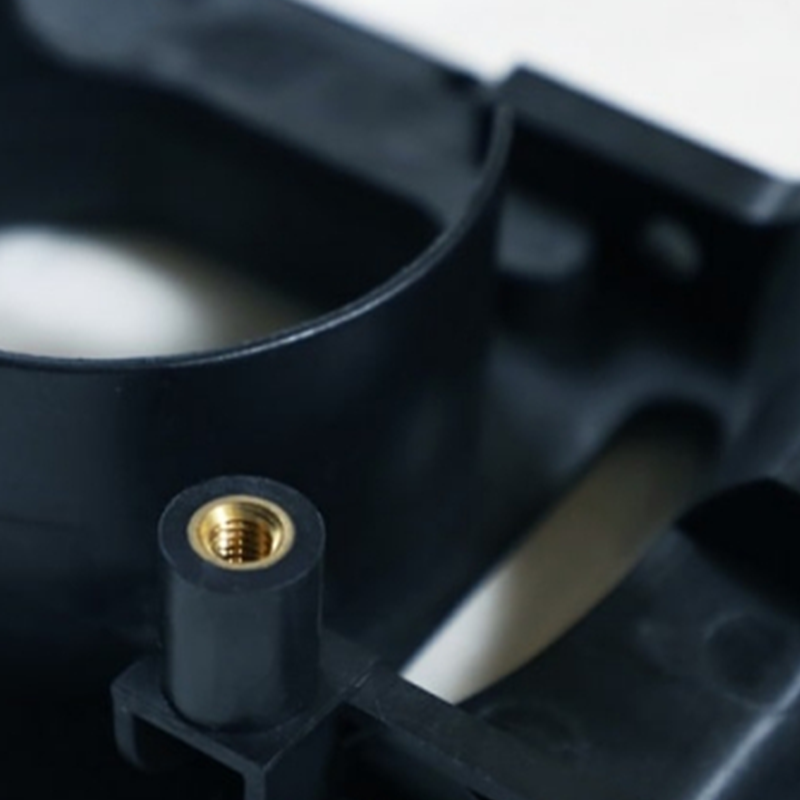

- Tooling Materials

Before the overmolding process starts low or high-volume production, a high-tolerance CNC machined tooling is needed. Most commonly used materials include:

Tool Steel: P20, H13, S7, NAK80, S136, S136H, 718, 718H, 738

Stainless Steel:

420, NAK80, S136, 316L, 316, 301, 303, 304

Aluminum: 6061, 5052, 7075

- Plastic Materials

Plastic injection molding service comes with a wide range of materials with different properties, including impact strength, rigidity, thermal resistance, chemical resistance, etc.

|

ABS |

Nylon (PA) |

PC |

PVC |

|

PU |

PMMA |

PP |

PEEK |

|

PE |

HDPE |

PS |

POM |

- Additives and Fibers

Standard plastic materials may not meet custom injection molding parts requirement. In this case, additives and fibers can be added to improve aesthetic and functional properties, providing additional features for your injection molded parts.

|

UV absorbers |

Colorants |

|

Flame retardants |

Glass fibers |

|

Plasticizers |

|

The Application of product

The injection overmolding process is compatible with a wide variety of materials, ranging from plastics to metals. This process helps produce custom prototypes and production parts for various applications depending on your requirements. Several industries find valuable uses for overmolding services.

- Surgical Instruments

Overmolding meets the precision and safety requirements of the medical industry. The ability to combine plastics and metal materials ensures the efficient creation of surgical devices, equipment housing, catheters, syringes, and more.

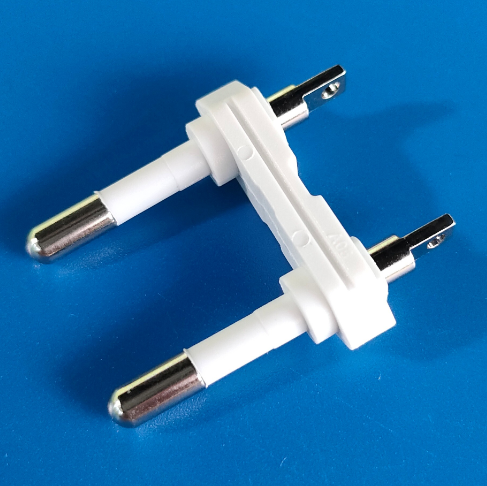

- Electrical Applications

Using thermoplastic elastomer as an overmold material makes the process useful for electrical components. Custom-made overmolded parts, like electrical outlet covers, gaskets, etc., are made to withstand harsh conditions, making them last longer.

- Hareware Tools

The functional advantages of overmolding make it an outstanding process for making pliers, screwdrivers, hammers, wrenches, pocket knives, and more. The process improves the grip of these tools, making their application more efficient.

- Household Items

The overmolding technique generally improves functional performance like grip, cleanliness, and ease of use. It also enhances vibration dampening, chemical resistance, and more. This makes them useful for household items like kitchen utensils, toothbrushes, pens, shampoo bottles, etc.

The Production Process of product

Our mold-making process includes 6 steps:

Step 1: Arrange production based on requirements.

Step 2: Provide detailed DFM report for feasibility analysis.

Step 3: Produce the mold and provide Tooling Schedule for client monitoring.

Step 4: Provide free samples for testing.

Step 5: Proceed with mass production after sample approval.

Step 6: Complete production, inspect quality, and store mold for future use.

Why Choose Us?

High-quality custom overmolding services for prototypes and on-demand production parts. Get online quotes, short cycle time and competitive pricing.

- No minimum order quantities

- Rapid Tooling Production as fast as 2 weeks

- ISO 9001:2015 certificated

- 24/7 engineering support