Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

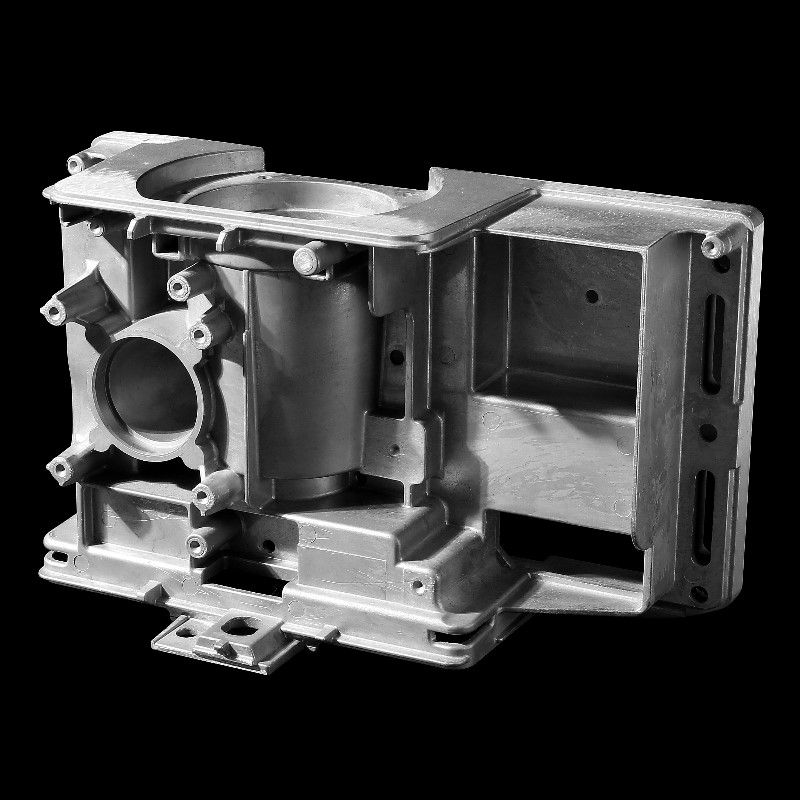

Metal Precision Casting

Precision casting refers to the general term for the process of obtaining precision-sized castings. Compared with the traditional sand casting process, the castings are obtained by precision casting have more precise dimensions and better surface finish. Its products are precise, complex, and close to the final shape of the part. Can be used directly without processing or processing.It is an advanced process of near-net-shape.

What is Precision Casting?

The process of precision casting encompasses various techniques, such as investment casting, ceramic casting, metal casting, pressure casting, and lost foam casting. Among these, investment casting, also known as lost wax casting, is widely employed for producing both ferrous and nonferrous metal castings.

In investment casting, the investment mold is created using a suitable material like paraffin. The mold undergoes multiple cycles of refractory coating and refractory sand processes, resulting in a hardened shell. After drying, the internal melting mold is melted off, creating a cavity. The baked shell obtains sufficient strength, and the remaining investment material is burned off, allowing the desired metal material to be poured. The process continues with solidification, cooling, shelling, and sand cleaning, ultimately producing a high-precision finished product. Subsequent heat treatment, cold working, and surface treatment are performed based on product requirements.

The Advantage of Product

- Perfect-Surface Finish

The investment casting process provides a far superior surface finish as compared to forgings and sand castings. Sometimes this is important and can avoid machining or other finishing operations.

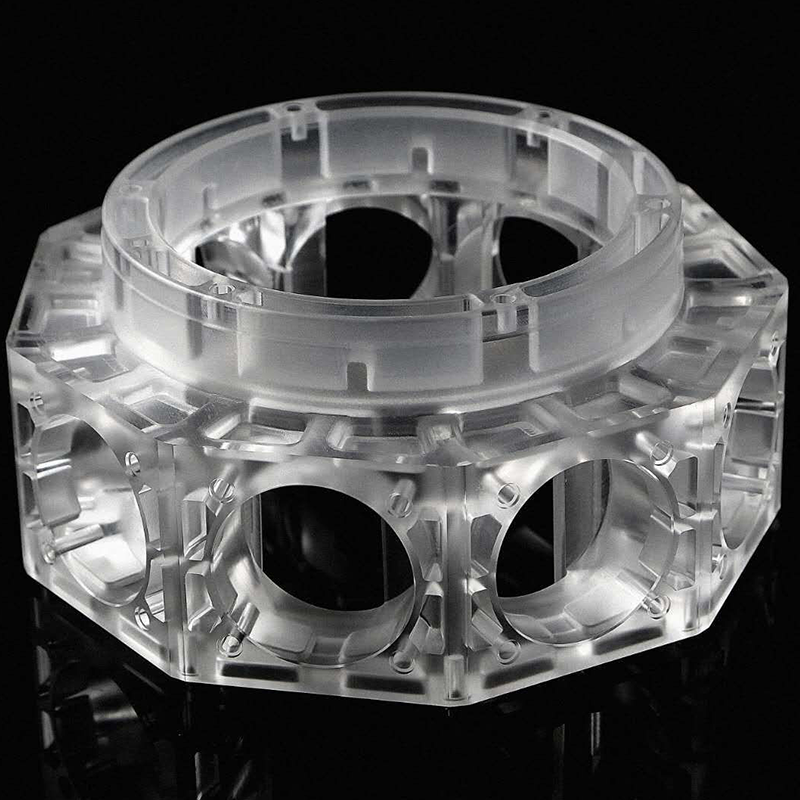

- Closer to finished part designs

Investment Castings provide near net shapes for manufactured parts, thus eliminating or reducing machining costs. Holes, undercuts, slots, and other difficult detail that cannot be had with other processes can often be provided. An added benefit of near net shape is the savings on material, especially with expensive alloys such as nickel and cobalt alloys.

- Tighter Tolerances

Due to the nature of the process, Investment Castings can be held to much tighter tolerances than sand castings or forgings.

- Competitive Tooling Costs

Initial charges for the investment casting tooling are often less expensive than those for sand castings.

- Thin wall castings

The investment casting process is capable of more reliable castings with much thinner walls than sand castings. Advantages include substantially fewer scrap rates and castings that weigh less due to the thinner wall capability.

- Less casting defects

Being a cleaner process than sand molds, investment castings, generally, provide a much higher percentage of defect free-castings.

- The Feature of Product

Precision casting provides substantial freedom in both design and material selection. It allows for the use of various types of steel or alloy steel, making it the preferred choice for high-quality castings in the market.

However, precision casting comes with challenges, notably in terms of molding cost and time. Each casting production necessitates a mold and one wax pattern, leading to increased time and separate costs.

Consequently, precision casting may not be a cost-effective solution for low-quantity products.

Despite this drawback, its unmatched quality makes precision casting the top choice for applications demanding the highest standards of precision and performance.

- The Application of product

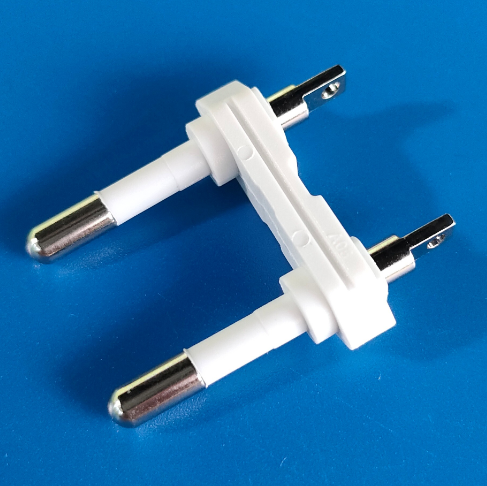

Precision casting products are used in all industrial sectors, especially electronics, petroleum, chemical, energy, transportation, light industry, textiles, pharmaceuticals, medical equipment, pumps and valves.

Precision casting products:

Aluminum casting: general aluminum casting | aluminum box;

Copper and aluminum castings: copper plates, copper sleeves | precision copper castings;

Steel castings: large steel castings | small steel castings | precision steel castings | CDL1 | CGAS | CGKD | CGKA | CGA;

Copper and aluminum castings;

Ferro Tungsten.

- The Production Process of product

Precision casting has many process steps, so it will take more time for each casting. If with a flow line to show. It is :

Waxing (wax mold)—repair wax—-wax inspection—-group tree (wax module tree)—shell (first paste, sand, re-slurry, finally Mould air drying)—Dewaxing (steam dewaxing)——-Mould roasting–chemical analysis–casting (casting molten steel in the mold shell)—-vibration shelling— Cutting and pouring of casting and pouring rod—-grinding gate—initial inspection (hairy inspection)—shot blasting—–machining—–polishing—finish inspection— Storage