Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

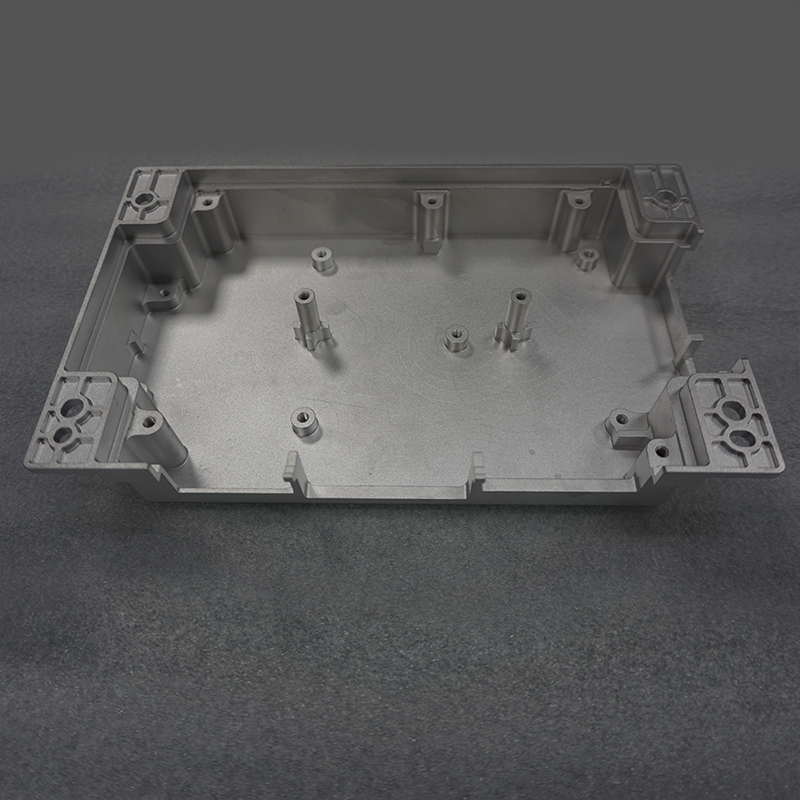

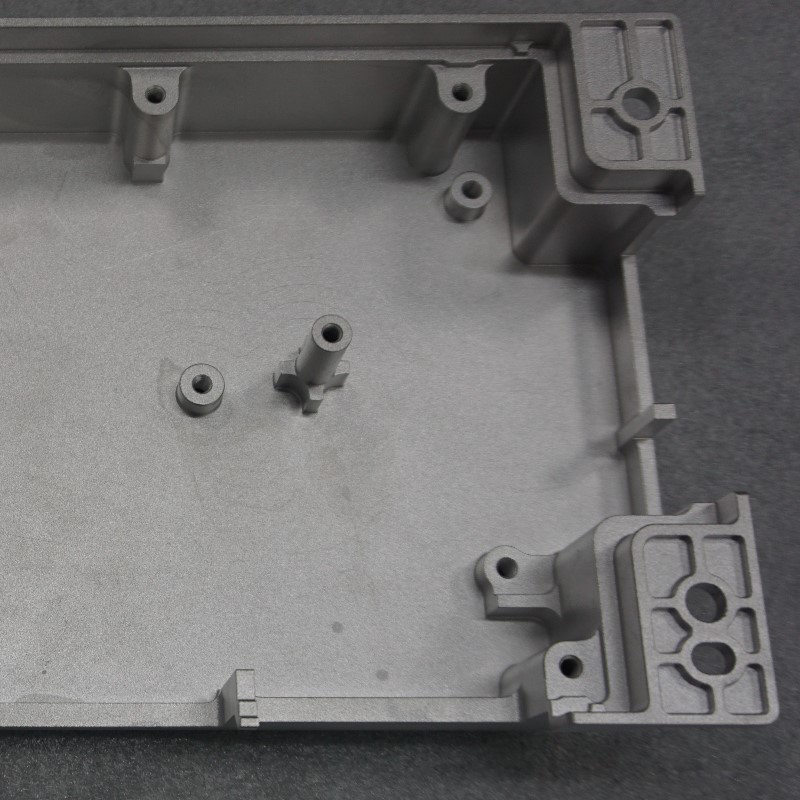

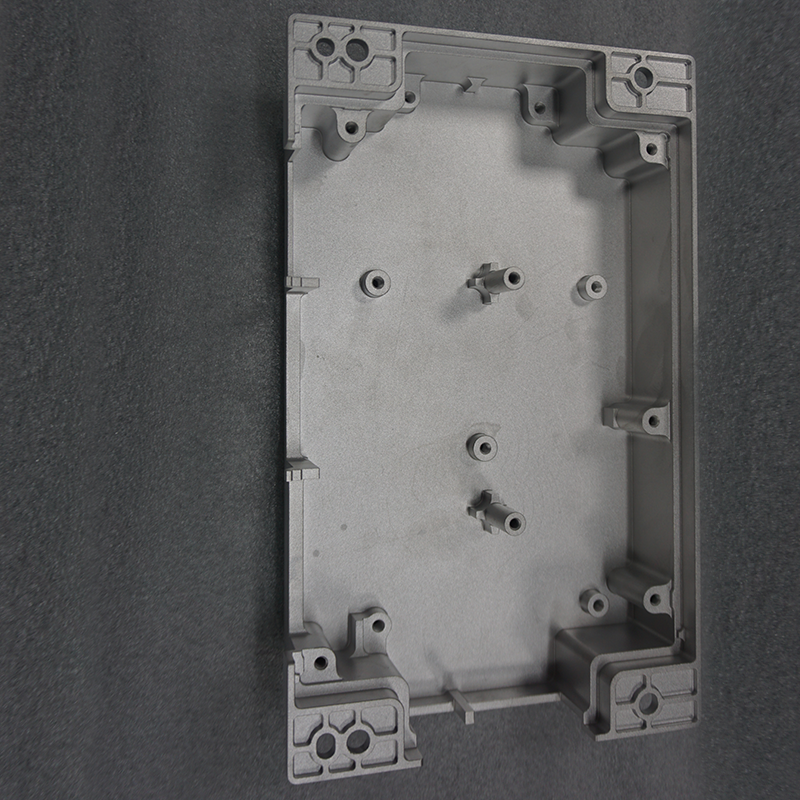

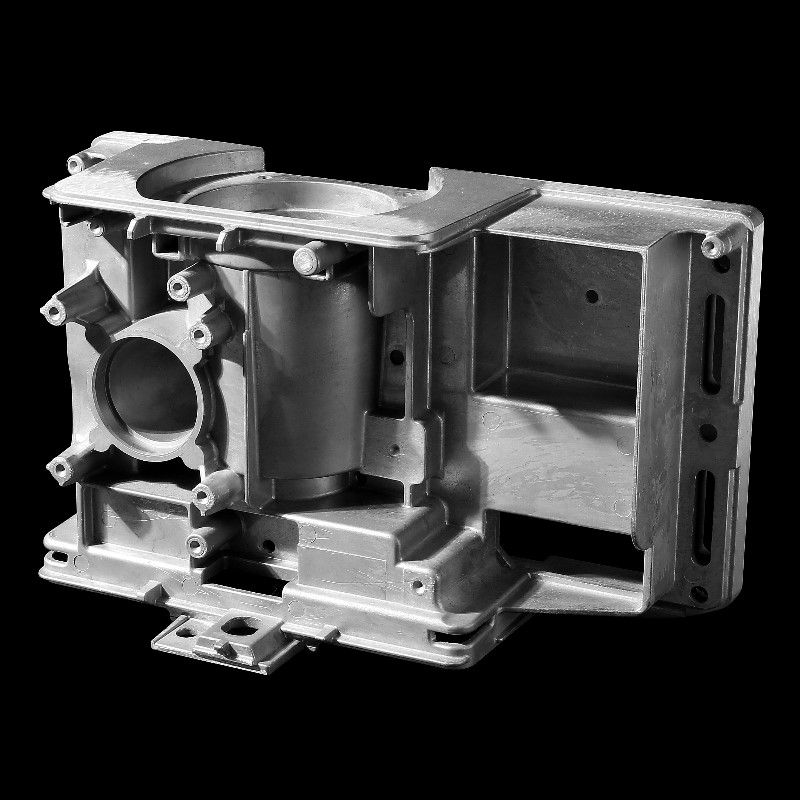

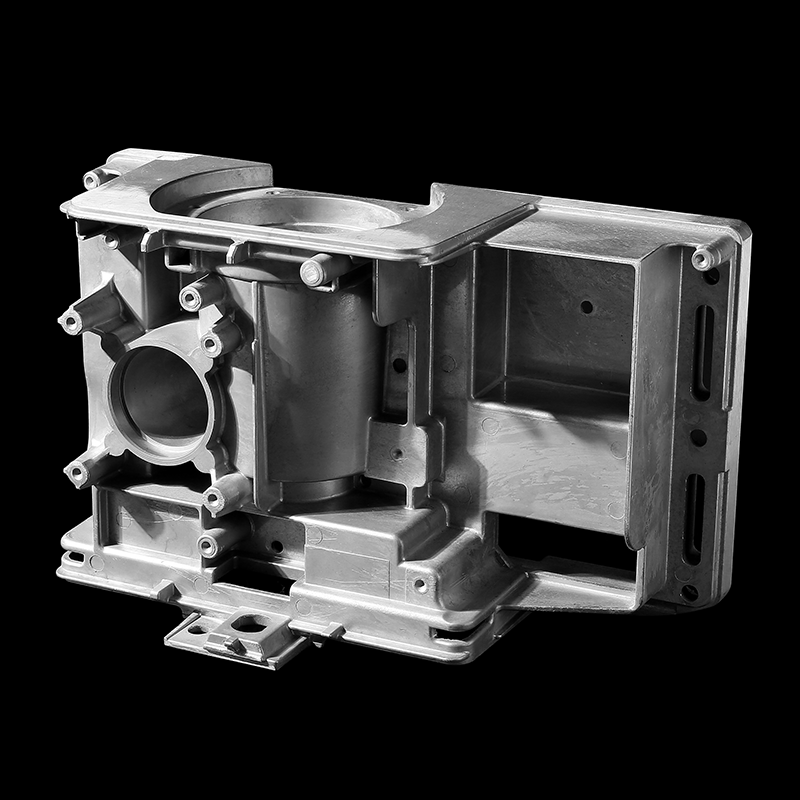

Metal Die Casting

Precision die casting services offer customized metal parts and products with swift turnaround times, making them an ideal solution for various manufacturing needs. If you're ready to get started, requesting a quote is the first step towards obtaining top-notch, tailor-made components.

Our Pressure Die Casting Services

Future Parts offer pressure die casting services which is great for manufacturing higher volumes of metal parts in aluminium, zinc or magnesium. We manufactures high quality die cast tools, offer precision die casting and post process machining and finishing options.

Die casting is the manufacturing process of choice when producing high volumes of relatively complex metal parts. These are two types of die casting capabilities we provide:

- Hot Chamber Die Casting

Hot chamber die casting, also known as gooseneck casting, is a considerably quick process with a typical casting cycle only 15 to 20 minutes. It allows for high volume manufacturing of comparatively complex parts.

The process is ideal for zinc alloy, lean alloys, copper and other alloys with low melting point.

- Cold Chamber Die Casting

Cold chamber die casting process is an very important procedure which helps reduce the amount of heat and solve the corrosion problem in machine’s plunder and related components.

The process is primarily used for alloys with high melting points, like aluminum, magnesium, some copper, and ferrous alloys.

Die Casting Technical Standards

|

Dimension |

Standards |

|

Minimum part weight |

0.017 kg |

|

Maximum part weight |

12 kg |

|

Minimum part size |

∅ 17 mm × 4 mm |

|

Maximum part size |

300 mm × 650 mm |

|

Minimum wall thickness |

0.8 mm |

|

Maximum wall thickness |

12.7mm |

|

Quality Control |

ISO 9001 Certified |

|

Minimum possible batch |

1000 pcs |

Die Casting Materials

- Magnesium

Magnesium metals are extremely light and have excellent stiffness & strength-to-weight ratio. It is commonly used make automotive components and electronical devices.

- Zinc Alloy

Zinc alloy has high strength and hardness, excellent electrical conductivity, high dimensional accuracy and stability. It can be used to make a variety of jewelry, art casting and mechanical applications.

- Aluminium

Aluminum is strong, light, cost-efficient and has great machinability, making it a popular choice in the aerospace and aviation, automotive, and consumer electronics industry.

The Advantage of product

Die Casting vs Metal Injection Moulding

Metal injection moulding, or MIM, is intricate and requires several steps to create parts. It is well suited for small intricate parts and large volume manufacturing. In comparison, die casting, has fewer steps and is economically feasible for smaller and larger runs when compared with MIM. It is used for creating larger geometrically complex components.

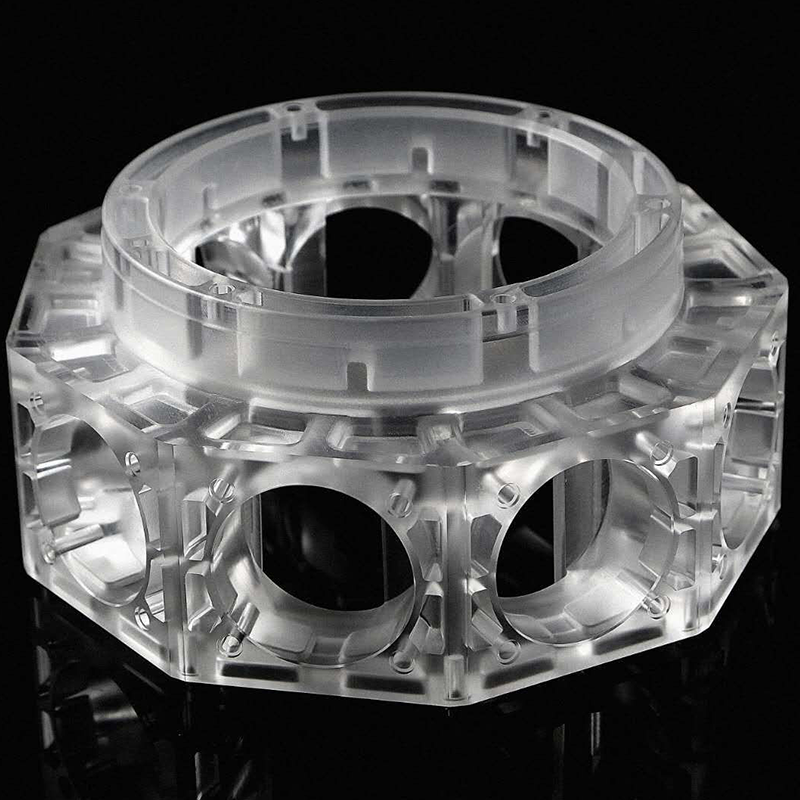

Die Casting is Used For

Producing (up to 100,000+) complex-shaped, industrial grade metal parts from real materials. Die casting is commonly used for making automotive components and decorative hardware.

Advantages of Die Casting:

- Lower cost per part

- Accurate and repeatable

- Good surface finish and range of treatments

- Good for larger and more complex parts

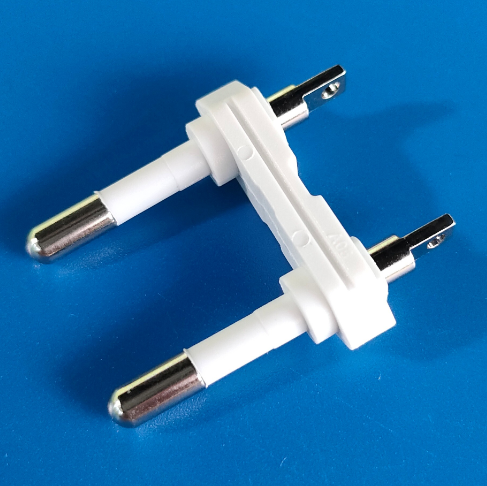

The Application of product

Die casting is a versatile manufacturing technique, and it plays an important role in creating and producing many modern products, from aerospace structural parts to electrical enclosures. Future Parts has provided innovative manufacturing solutions for different industrial applications:

- Automotive Parts: As die cast parts manufacturer, we specialize in making vehicle parts like gears, cylinders, gladhands, transfer cases, small engine parts, and even components for lawn and garden tractors.

- Aerospace Industry: Magnesium and aluminum pressure die casting technologies from precision die casting service can produce light, durable structural parts with great resistance to corrosion.

- Lightning Components: Our die casting service is also for electrical housings, die cast heat sinks, and many more components.

- Commercial & Consumer Products: We also manufacture commercial parts including compressor pistons and connecting rods, heat sinks, bearing housings, parts of the sink faucet, meters.

The Production Process of product

There are 5 steps to produce die casting products.

Step 1: Prepare mold by heating and coating the interiors.

Step 2: Inject molten metal into the mold under pressure.

Step 3: Allow the metal to cool and harden to form the desired shape.

Step 4: Carefully unclamp the mold and remove the cast part.

Step 5: Trim the casting part to achieve the desired component shape.

Why Choose Us?

Die Casting Services

Precision die casting service for customized metal parts and products with fast turnaround times. Request a quoting to get started today.

Tolerance down to ± 0.004'' (0.1 mm)

7/24 technical support

ISO 9001:2015 certified manufacturing partner