Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

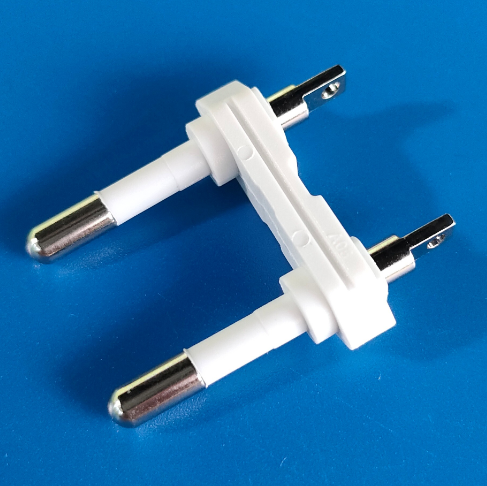

Insert Molding

Insert molding is the innovative solution for seamless integration! With Insert Molding, you can effortlessly combine different materials, creating a sturdy and functional product that meets your specific needs.Our cutting-edge technology allows for the insertion of various components, such as metal or plastic, into the mold during the molding process. This ensures a secure and reliable bond, eliminating the need for additional assembly steps

What's Insert Molding

Insert molding is an injection molding technique that involves injecting a plastic material around a plastic or metal insert placed in a mold cavity. The insert is pre-placed in the mold cavity, after which the plastic is injected. On cooling, this forms a solid part that is strong and durable. Future Parts plastic insert molding services allow you to make a strong and permanent bond between the insert and molded plastic.

- Eliminate assembly: Insert molded parts do not require assembly because there is only one manufacturing process.

- Reduce costs: The removal of the assembly process reduces the cost of the insert molding process compared to the standard injection molding.

- Reduced part size and weight: Insert molded parts that weigh less than all-metal parts.

- Improve part strength: Incorporating plastic and metal inserts increases the durability and strength of the parts compared to other injection molding processes.

Specification:

Future Parts’s insert molding solutions manufacture parts with different functional and aesthetical needs. These guidelines will help improve part manufacturability, reduce lead time, and improve the part aesthetics. You can check the following standard design considerations:

|

Standards |

Metric Units |

Imperial Units |

|

Maximum Part Size |

800×1000×400mm |

31.50×39.37×15.75in |

|

Minimum Part Size |

2×2×2mm |

0.08×0.08×0.08in |

|

Substrate Wall Thickness |

0.5~3 mm |

0.20~0.12 in |

|

Tolerance |

±0.025mm |

±0.00098 in |

|

Insert |

Inserts can be female and male. They both can improve a product’s appearance and utility. |

|

|

Mold Validation |

Provide T0, T1, T2 samples before mass production |

|

|

Inspection and Certifiaction |

First Article Inspection, ISO 9001, ISO 13485 |

|

|

Lead Time |

From mold making to sample delivery: 15-45 business days |

|

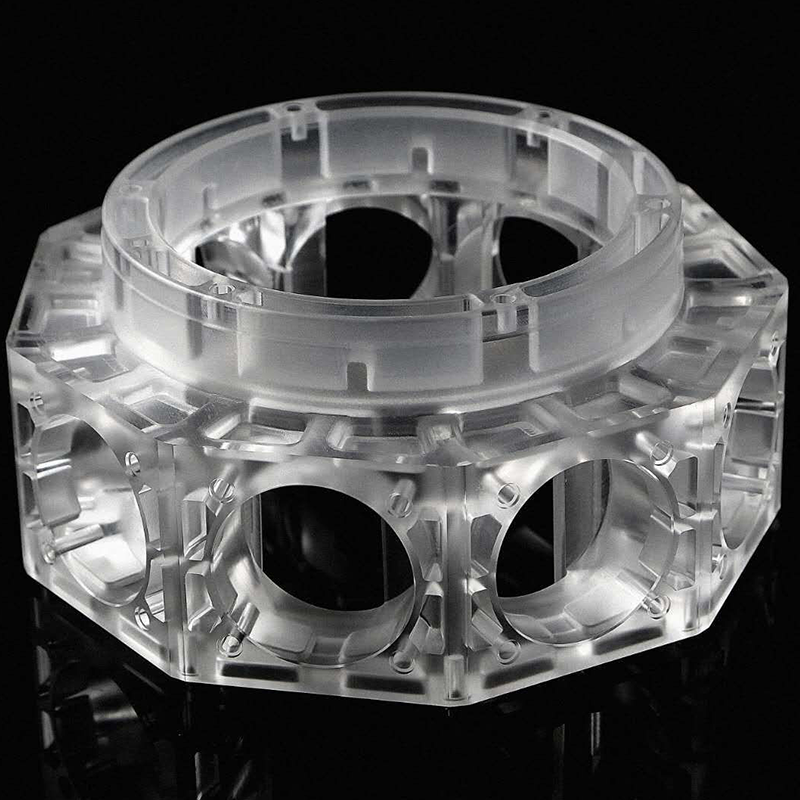

Materials for Insert Molding

We provide a wide range of materials for thermoplastic and inserts that can help you make insert molded parts of different industrial applications. Below are the materials used in custom plastic insert molding and common examples.

- Tooling Materials

Before the overmolding process starts low or high-volume production, a high-tolerance CNC machined tooling is needed.

Most commonly used materials include:

Tool Steel: P20, H13, S7, NAK80, S136, S136H, 718, 718H, 738

- Stainless Steel

420, NAK80, S136, 316L, 316, 301, 303, 304

Aluminum: 6061, 5052, 7075

- Plastic Materials

Plastic injection molding service comes with a wide range of materials with different properties, including impact strength, rigidity, thermal resistance, chemical resistance, etc.

|

ABS |

Nylon (PA) |

PC |

PVC |

|

PU |

PMMA |

PP |

PEEK |

|

PE |

HDPE |

PS |

POM |

- Additives and Fibers

Standard plastic materials may not meet custom injection molding parts requirement. In this case, additives and fibers can be added to improve aesthetic and functional properties, providing additional features for your injection molded parts.

|

UV absorbers |

Colorants |

|

Flame retardants |

Glass fibers |

|

Plasticizers |

|

- Inserts

The introduction of inserts onto mold cores cast using the manual or automated process leads to the plasticization of plastic pellets after closing the mold halves. Ejection of the pieces from the mold takes place after the plastic’s hardening, followed by the encapsulation of the inserts in the parts.

|

Brass |

|

Stainless Steel |

|

Aluminum |

Why Choose Us?

Custom insert molding services for high-quality prototypes and on-demand parts. Get online quotes at a competitive price and short lead time.

- No minimum order quantities

- Rapid Tooling Production as fast as 2 weeks

- ISO 9001:2015 certificated

- 24/7 engineering support

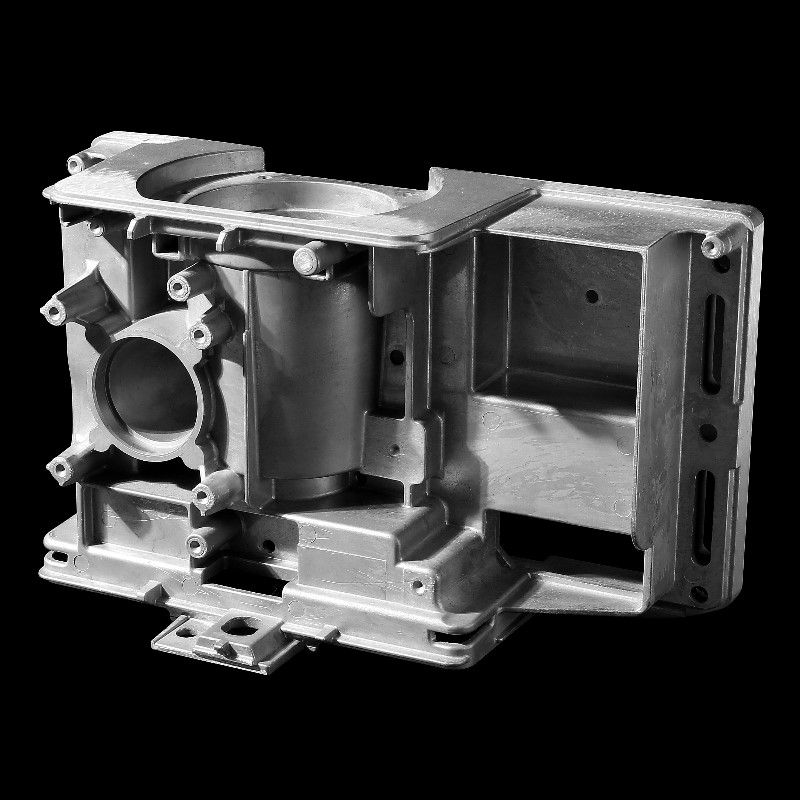

The Application of product

Insert Molding Applications

Plastic insert molding is applicable in making prototypes and full products in several industries. Key industrial applications of insert molding include:

- Consumer Goods

The custom plastic insert molding is suitable for making consumers good due to its functional and aesthetic benefits.

- Medical Devices

Ensure the plastic is biocompatible before you choose insert molding to make devices and products such as medical implants.

- Aerospace and Automotive

Applicable in making handheld devices such as screwdrivers, scissors, dials, and knobs.

- Communication Devices

Applicable in the aerospace and automotive industry due to the strength and durability of molded parts.