Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

MJP 3D Printing Service

At Future Parts, we offer cutting-edge Multi-Jet Printing (MJP) 3D printing services powered by 3D Systems. This advanced technology enables us to produce parts and prototypes with exceptional speed and accuracy, matching the precision of your CAD designs.

MJP takes 3D printing to the next level by offering Ultra High Definition mode, allowing for the creation of even smaller features with incredible detail. With MJP, we can achieve resolutions as fine as 300 microns or finer, ensuring that every intricate detail of your design is faithfully reproduced.

Specification

|

Maximum Build Size |

294 x 211 x 144 mm (11.6″ x 8.3″ x 5.7″) |

|

Lead Time |

2-3 days |

|

Resolution |

± 0.3mm |

|

Prototyping Applications |

Visually aesthetic, complex-shaped and detailed concept models |

|

End-Use Applications |

Low-volume, detailed and functional end use parts |

MJP Materials

MG2-CL has a great balance of strength and toughness with a clear aesthetic.It is versatile across a wide range of applications and delivers advanced prototyping performance to meet almost any engineering need.

Appearance:Transparent

Typical MJP Finishing Options

|

|

Applicable Materials |

Colour |

Description |

|

As Printed |

– |

Transparent |

MJP printed parts are often left as printed, as they are naturally aesthetic and have an excellent smooth finish. |

|

Painting |

All |

Black,pantone/ RAL colours |

Painting is a way to add colour and a great way to improve the aesthetics of MJP parts. |

|

Dyeing |

All |

Black,pantone/ RAL colours |

Dyeing is the fastest and most cost-effective way to colour MJP printed parts. It is mainly used to improve aesthetics. |

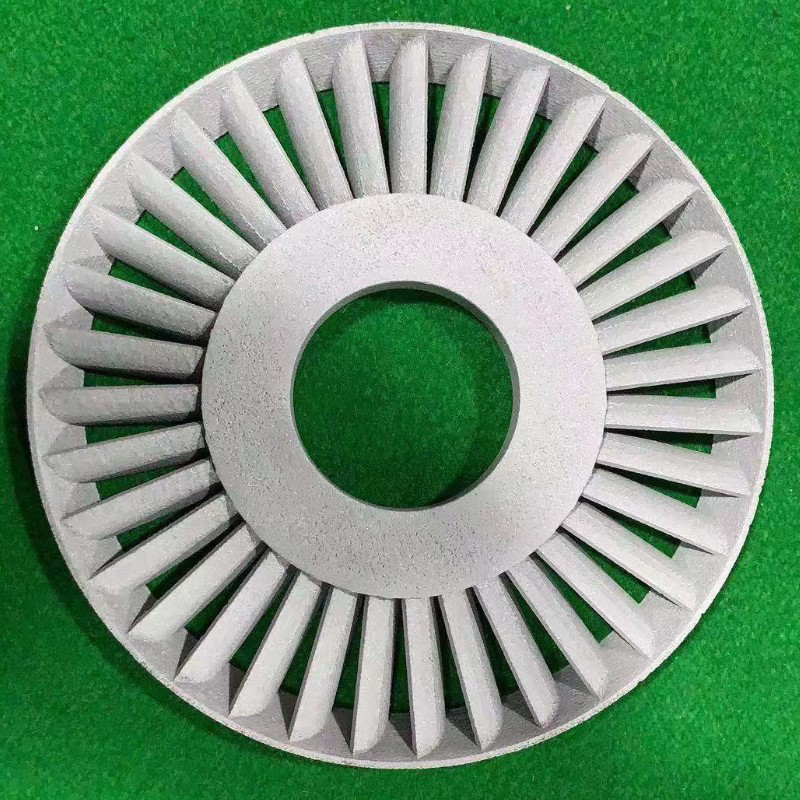

The Advantage of product

- High Resolution Prints

Due to its 3D printing process, MultiJet Printing enables 3D printing of high-resolution prototypes with the finest details

- Complex Geometries

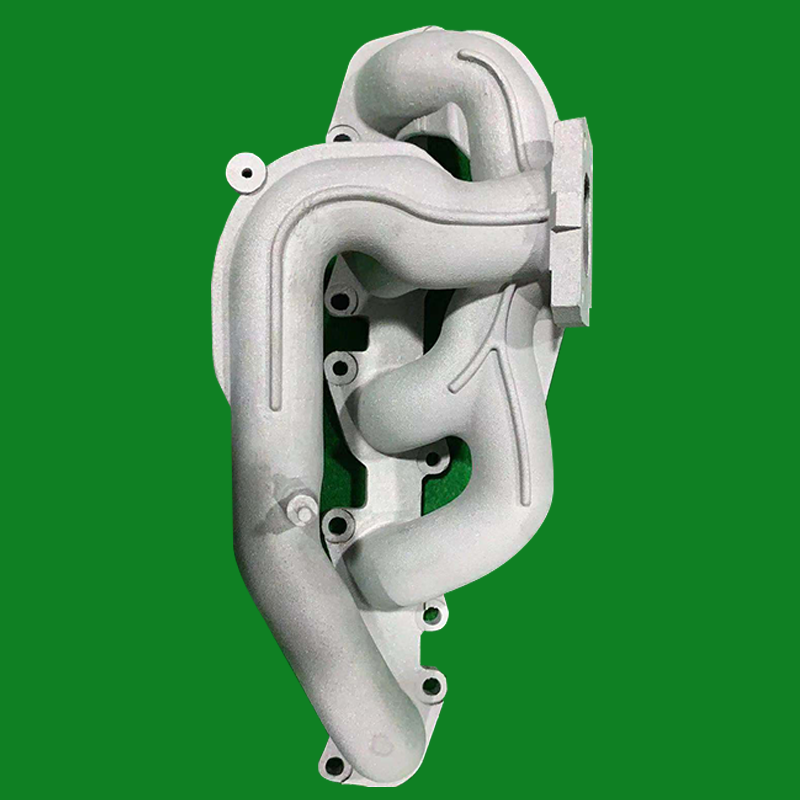

Complex geometries can be built more easily due to the 3D printing process, adding complexity without additional cost.

- Rapid Turnaround

Parts can typically be shipped in 2-3 days, allowing for faster design iterations and speed to market.

- Production Parts

MJP is capable of producing end-use parts and prototypes on-demand. It si often used in the medical industry.

The Application of product

MJP is a fantastic choice for high resolution, detailed parts and models. Often used for concept modelling and communication, sales and marketing models. The high speed throughput makes it a great choice for rapid design iteration for rigid plastic or elastomeric products. Some of the materials enable biocompatible medical devices to be made quickly. It can also be used for jigs, fixtures and tools.

The advantages of MJP make it applicable in many industries, including the automotive, aerospace, medical and electronics industries.

The Production Process of product

MultiJet Printing or MJP is a fairly new additive manufacturing technology introduced to the industry in 2016. It uses a UV-cured resin and produces high detail, high resolution parts.