Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

FDM 3D Printing Service

Fused Deposition Modeling (FDM) is a widely recognized and versatile 3D printing technology. It is often the first thing that comes to mind when people think of 3D printing. However, FDM is often misunderstood and mistakenly believed to be limited to basic prototypes and models.

FDM technology allows for the creation of functional parts with complex geometries and intricate designs. It enables the production of parts with high accuracy and precision, meeting the requirements of demanding applications in different industries.In reality, FDM parts find applications in various industries, including aerospace, automotive, and many others.

Specification

|

Maximum Build Size |

750 x 750 x 750 mm (29.5″ x 29.5″ x 29.5″) |

|

Lead Time |

2-3days |

|

Resolution |

± 0.3mm |

|

Prototyping Applications |

Low-fidelity, proof-of-concept prototyping and visual design verification. |

|

End-Use Applications |

Low-volume end parts, such as jigs and fixtures. |

|

|

Description |

Material Reference |

Appearance |

|

PA |

Nylon filament(PA) is an extremely durable material with great strength to flexibility ratio, which becomes an alternative to standard PLA or ABS. This filament is commonly used for semi-flexible and mechanical parts since its chemical, wear and UV resistance is higher compared with basic 3D printing plastics. |

Nylon12CF, Nylon12, Nylon6 |

Black, White, Beige |

|

High Performance Material |

High performance plastics are plastics that meet higher requirements than standard or engineering plastics. They have high thermal stability, superior mechanical properties, and outstanding chemical resistance. |

TPU92A, ULTEM1010, PPSF/PPSU, ULTEM9085 |

|

|

PLA |

FDM PLA (polylactic acid) is highly versatile. It prints reliably with high dimensional accuracy and a quality surface finish. As such, it is ideal for a range of applications – from detailed prototypes to simple manufacturing jigs and gauges. |

Tough PLA, PLA Ivory (biodegradable) |

Many Colours |

|

ABS |

FDM ABS is a rigid, tough, heat resistant material that offers superior aesthetics. It is a great choice for creating functional prototypes and complex end-use parts. |

ABS-M30,ABS-M30i, ABSi, ABS-ESD7 |

Many Colours |

|

PC |

PC has high impact resistance, wear resistance and can withstand functional testing. It is commonly used in the medical, automotive and telecommunications industries. |

PC-ABS, PC-ISO, PC |

White, Transparent |

|

ASA |

ASA (Acrylonitrile styrene acrylate), also called acrylic styrene acrylonitrile, is as tough and dependable as ABS filaments. Though it offers less impact resistance, ASA is much more UV-stable than ABS, hence is better for outdoor applications. |

ABS-like |

Many Colours |

Typical FDM Finishing Options

| Applicable Materials | Colour | Description | |

| Bead Blasting | All | _ | Bead blasting may offer a more comprehensive solution for smoothing, especially for complex parts with hard-to-reach areas. |

| Painting | All | Black, Pantone/ RAL Colours | Painting is a way to add colour and hide layer lines, overall, a great way to improve the aesthetics of FDM parts. |

| Plating | BS | Metallic | Plating is method of adding a thin layer of metal of the outer layer of a material. It is used to harden, decorate and improve wearability of parts. |

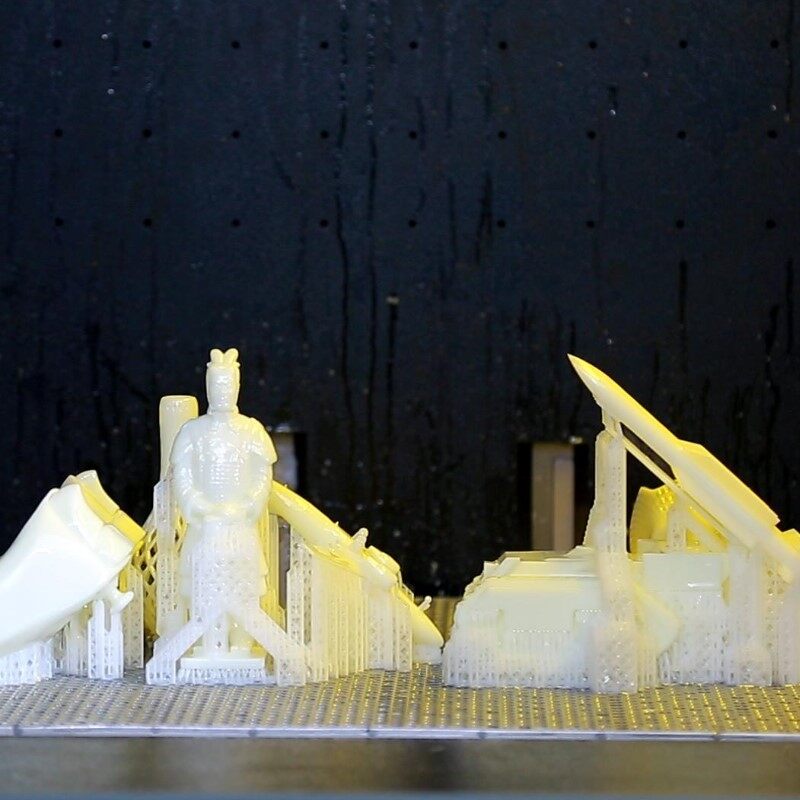

The Advantage of product

- Large Build

We have industrial FDM printers suitable for producing large parts up to 800 x 800 x 550 mm (31.5″ x 31.5″ x 21.6″).

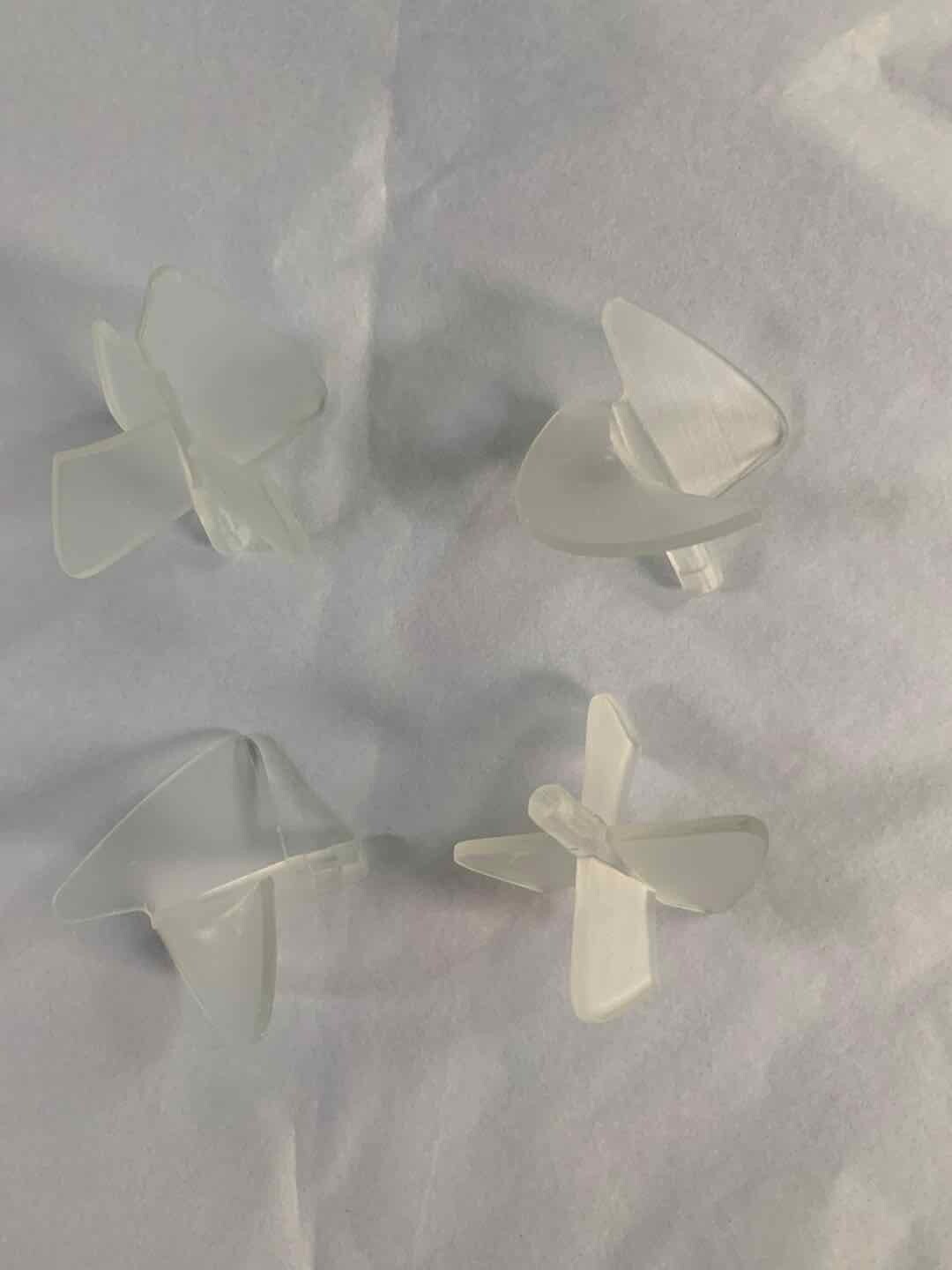

- Complex Geometries

Geometries that are too complex or costly for CNC machining can be printed easily, allowing you to add complexity without additional cost.

- Rapid Turnaround

FDM is one of the fastest method to create a quick prototype, reducing the manufacturing lead time from weeks to days. It allows for faster innovation and speed to market.

- Strength

FDM printed parts are available in a variety of high-performance plastics for applications that require resistance to the elements.

FDM 3D Printing is often used to create industrial-strength, high-performance parts in the aerospace, automotive, robotics, and electronics industries.

The Production Process of product

FDM extrudes a plastic filament material through a nozzle, laying it down one layer at a time. It can make parts with complex geometries as well as simple housings and fixtures.