Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

The Power of OEM Steel Plasma Cutting Services: A Comprehensive Guide

In the ever-evolving world of manufacturing and fabrication, precision and efficiency are key. Among the various cutting technologies available, steel plasma cutting has emerged as a favorite for its speed, accuracy, and versatility. When you add the OEM (Original Equipment Manufacturer) angle to this, the benefits and possibilities become even more compelling. In this blog post, we'll delve into the world of OEM steel plasma cutting services, exploring why this technology is a game-changer for industries worldwide.

What is Steel Plasma Cutting?

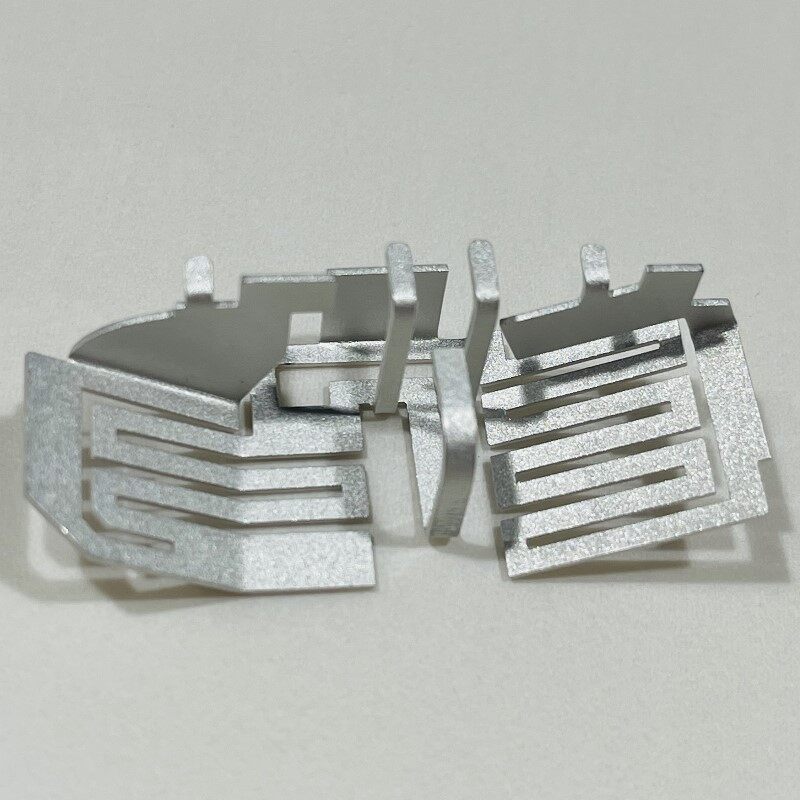

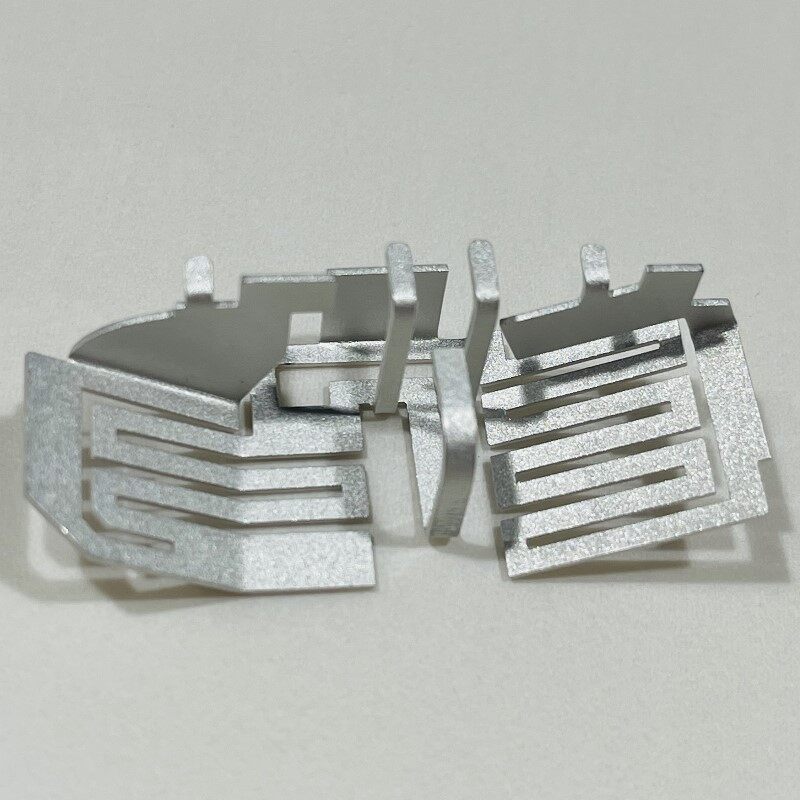

Steel plasma cutting is a method used to cut through electrically conductive materials using a plasma torch. This process involves ionizing a gas to create a plasma arc, which then melts the steel and blows away the molten material, resulting in a clean and precise cut. It’s known for its speed and ability to cut through thick steel plates with remarkable accuracy.

The Role of OEM in Plasma Cutting Services

OEM steel plasma cutting services take the benefits of plasma cutting and tailor them to meet specific client needs. When companies opt for OEM services, they are choosing a bespoke approach that aligns perfectly with their requirements. OEM providers work directly with businesses to develop customized solutions, offering tailored cutting services that can handle unique specifications and complexities.

Advantages of OEM Steel Plasma Cutting Services

1. Precision and Accuracy

OEM steel plasma cutting services offer unparalleled precision. The technology allows for intricate cuts with minimal waste, ensuring that every component is manufactured to exact specifications. This level of accuracy is essential for industries where even minor deviations can lead to significant issues, such as aerospace or automotive manufacturing.

2. Customization

One of the primary advantages of choosing OEM steel plasma cutting services is the ability to customize. OEM providers are adept at handling specific requirements, whether it’s a particular thickness of steel, custom shapes, or intricate designs. This customization ensures that the end product fits perfectly with the overall project requirements, enhancing both functionality and aesthetics.

3. Cost-Effectiveness

While initial costs for OEM steel plasma cutting services might be higher than standard cutting methods, the long-term savings are significant. The efficiency of plasma cutting reduces material waste and minimizes the need for secondary processing, leading to lower overall production costs. Furthermore, the precision of OEM services reduces the likelihood of costly errors and reworks.

4. Speed and Efficiency

In a competitive market, time is often of the essence. OEM steel plasma cutting services excel in delivering fast turnaround times without compromising quality. The speed of plasma cutting means that large volumes of steel can be processed quickly, which is crucial for meeting tight deadlines and maintaining production schedules.

5. Versatility

OEM steel plasma cutting services are versatile and can handle a variety of steel types and thicknesses. Whether it’s mild steel, stainless steel, or aluminum, OEM providers have the expertise and equipment to manage diverse cutting requirements. This versatility is a significant advantage for industries that work with multiple types of steel or have varying project needs.

Applications of OEM Steel Plasma Cutting Services

1. Automotive Industry

In the automotive industry, precision and durability are paramount. OEM steel plasma cutting services provide the exacting standards required for automotive parts, ensuring that each component fits perfectly and performs reliably. From chassis parts to engine components, plasma cutting supports the high standards of automotive manufacturing.

2. Aerospace Sector

The aerospace sector demands the highest levels of accuracy and quality. OEM steel plasma cutting services meet these stringent requirements, providing components that meet rigorous safety and performance standards. Plasma cutting’s ability to handle complex designs and precise tolerances makes it ideal for aerospace applications.

3. Construction

In construction, steel components are often used for structural support and architectural features. OEM steel plasma cutting services ensure that these components are cut to the exact specifications needed for safe and effective construction. Custom shapes and sizes can be achieved to meet the specific needs of various construction projects.

4. Industrial Machinery

OEM steel plasma cutting services are also essential for the industrial machinery sector. Machinery components often require precise cuts and custom designs to function correctly. Plasma cutting provides the accuracy needed for manufacturing parts that will operate efficiently in demanding industrial environments.

Choosing the Right OEM Steel Plasma Cutting Service

Selecting the right OEM steel plasma cutting service provider is crucial for ensuring quality and efficiency. Here are some tips for making the right choice:

1. Expertise and Experience

Look for a provider with extensive experience in steel plasma cutting. An experienced OEM service provider will have the knowledge and skills needed to handle complex projects and deliver high-quality results.

2. Technology and Equipment

Ensure that the provider uses advanced technology and state-of-the-art equipment. Modern plasma cutting machines offer superior precision and capabilities, so choosing a provider with up-to-date technology is important.

3. Customization Capabilities

Assess the provider’s ability to handle custom requirements. OEM steel plasma cutting services should be able to accommodate specific designs and specifications, ensuring that the final product meets your exact needs.

4. Quality Assurance

Quality assurance is essential for any manufacturing process. Choose a provider that has robust quality control measures in place to ensure that every cut meets the highest standards.

5. Customer Support

Good customer support can make a significant difference. Select a provider that offers excellent customer service, including clear communication and support throughout the project.

Conclusion

OEM steel plasma cutting services offer a powerful solution for industries requiring precise, efficient, and customized cutting solutions. The combination of advanced technology, customization options, and cost-effectiveness makes it an attractive choice for various applications. By partnering with the right OEM service provider, businesses can benefit from high-quality results that meet their specific needs and enhance their production capabilities. Whether in automotive, aerospace, construction, or industrial machinery, OEM steel plasma cutting services are a game-changer in the world of manufacturing.