Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

In the fast-paced world of electronics manufacturing, Surface Mount Technology (SMT) machines play a crucial role in ensuring efficient and accurate assembly of electronic components onto printed circuit boards (PCBs). To maintain the smooth functioning of these machines and maximize their lifespan, regular maintenance is essential. In this blog post, we will delve into the significance of SMT machine maintenance and explore the benefits it brings to the manufacturing process.

1. Understanding SMT Machines?

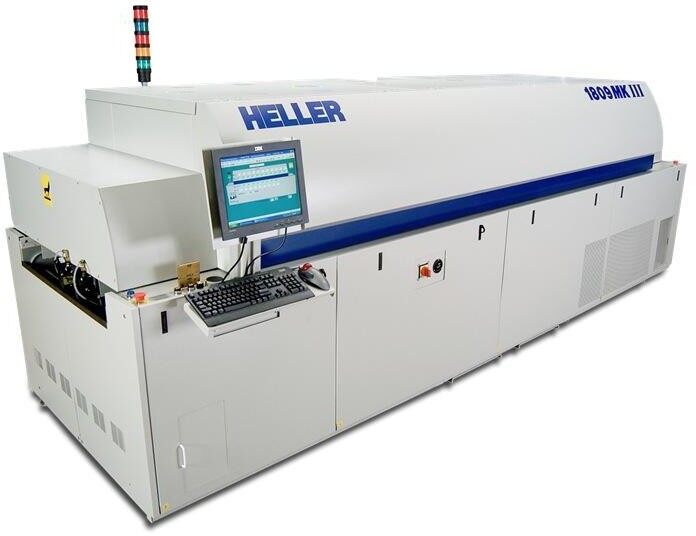

SMT machines, such as Siemens SMT machine, Fuji SMT machine, or Panasonic SMT machine, are automated systems that place electronic components onto PCBs. These machines utilize advanced technology to achieve high-speed and precise assembly. However, like any other machinery, they require proper care and maintenance to operate at their full potential.

2. The Importance of Regular SMT Machine Maintenance?

a. Longevity of Equipment: Regular maintenance plays a vital role in extending the lifespan of SMT machines. By following a scheduled maintenance plan, manufacturers can identify and address potential issues before they escalate into major problems. This proactive approach helps prevent premature wear and tear, ensuring that the machines continue to function optimally for an extended period.

b. Minimized Downtime: Unexpected breakdowns can significantly disrupt the manufacturing process, leading to costly production downtime. Regular maintenance helps identify and rectify potential issues before they cause machine failures. By addressing these issues proactively, manufacturers can minimize the risk of unplanned downtime and keep their production lines running smoothly.

c. Consistent Output Quality: SMT machines are responsible for placing electronic components onto PCBs with precision and accuracy. Regular maintenance ensures that the machine’s components, such as feeders, nozzles, and conveyors, are clean and free from debris. This cleanliness is crucial for preventing clogs and ensuring smooth operation, ultimately resulting in consistent and high-quality output.

d. Cost Savings: Investing in regular maintenance is a cost-effective approach compared to dealing with major repairs or equipment replacements. By identifying and addressing minor issues during routine maintenance, manufacturers can prevent these problems from escalating into more significant and costly repairs. Additionally, well-maintained machines are less likely to experience unexpected breakdowns, reducing the need for emergency repairs and minimizing production delays.

e. Enhanced Safety: Regular maintenance not only ensures the optimal performance of SMT machines but also contributes to a safer working environment. During maintenance checks, technicians can inspect the machine’s electrical connections, belts, and motors for any signs of wear or damage. Timely detection and repair of these issues help prevent potential safety hazards, protecting both the operators and the equipment.

f. Compliance with Industry Standards: In industries with strict quality control requirements, such as automotive or aerospace, compliance with industry standards is crucial. Regular maintenance helps ensure that SMT machines meet these standards by keeping them in optimal condition. This includes regular calibration of sensors, cameras, and placement heads to maintain accuracy and precision, as well as software updates to incorporate the latest industry requirements.

g. Improved Overall Efficiency: Well-maintained SMT machines operate at peak efficiency, reducing cycle times and increasing production output. By keeping the machines in optimal condition, manufacturers can maximize their productivity and overall efficiency. This, in turn, leads to cost savings, improved customer satisfaction, and a competitive edge in the market.

3. Key SMT Machine Maintenance Practices?

To keep SMT machines in optimal condition, the following maintenance practices should be implemented:

a. Cleaning: Regular cleaning of the machine’s components, such as feeders, nozzles, and conveyors, is essential to remove dust, debris, and solder residues. This prevents clogging and ensures smooth operation.

b. Lubrication: Proper lubrication of moving parts, such as rails and bearings, reduces friction and wear, extending the machine’s lifespan. It is important to use the recommended lubricants and follow the manufacturer’s guidelines.

c. Calibration: Regular calibration of the machine’s sensors, cameras, and placement heads is necessary to maintain accuracy and precision. This ensures that components are placed correctly on the PCBs, minimizing defects and rework.

d. Inspection: Routine inspection of the machine’s belts, motors, and electrical connections helps identify any signs of wear or damage. Timely detection allows for prompt repairs, preventing further complications.

e. Software Updates: Keeping the machine’s software up to date is crucial for optimal performance. Software updates often include bug fixes, performance enhancements,and new features that improve efficiency and reliability.

4. Benefits of SMT Machine Maintenance?

Implementing regular maintenance practices for SMT machines brings several benefits to the manufacturing process:

a. Improved Efficiency: Well-maintained machines operate at peak efficiency, reducing cycle times and increasing production output. This leads to improved overall efficiency and cost-effectiveness.

b. Enhanced Product Quality: Regular maintenance ensures that components are placed accurately, minimizing defects and rework. This results in higher product quality and customer satisfaction.

c. Reduced Downtime: By preventing unexpected breakdowns and addressing potential issues proactively, maintenance helps minimize production downtime. This leads to uninterrupted manufacturing processes and increased productivity.

d. Cost Savings: Investing in regular maintenance is a cost-effective approach compared to dealing with major repairs or equipment replacements. It helps extend the lifespan of the machines and reduces the risk of costly production delays.

e. Compliance with Industry Standards: Regular maintenance ensures that SMT machines comply with industry standards and regulations. This is particularly important in industries with strict quality control requirements, such as automotive or aerospace.

Conclusion: SMT machine maintenance is a critical aspect of electronics manufacturing. By implementing regular cleaning, lubrication, calibration, inspection, and software updates, manufacturers can ensure the longevity and optimal performance of their SMT machines. The benefits of maintenance include improved efficiency, enhanced product quality, reduced downtime, cost savings, and compliance with industry standards. Prioritizing the SMT machine maintenance not only maximizes the lifespan of the machines but also contributes to the overall success of the manufacturing process.

We are from professional SMT machine factory, that can wholesale SMT machines to meet your specific needs, no matter which type number that you need, we can all well make it well! Our commitment is to make our customers satisfied with cheap price and premium quality. If you have any problem about the SMT machines, please just contact with us.