Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

In the fast-paced world of electronics manufacturing, having reliable and efficient Surface Mount Technology (SMT) equipment is crucial. SMT equipment supplier plays a vital role in providing manufacturers with the necessary tools and machinery to streamline their production processes. In this blog post, we will explore the importance of choosing the right SMT equipment suppliers and provide valuable insights into sourcing high-quality equipment.

1. Understanding the Role of SMT Equipment Suppliers?

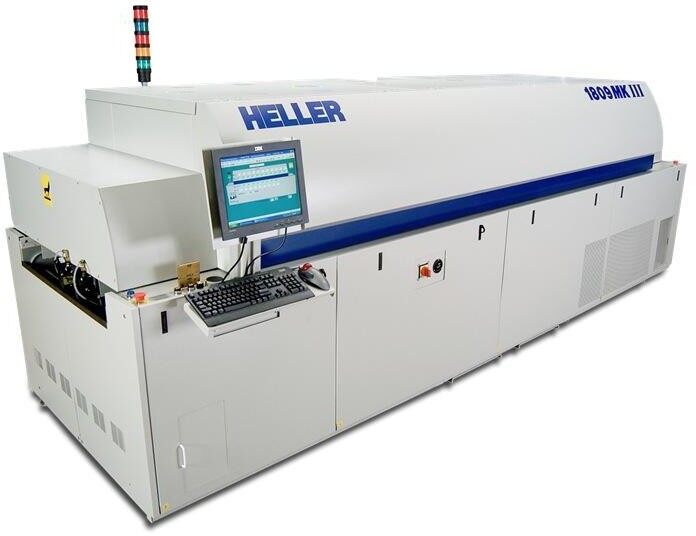

SMT equipment supplier are company that specializes in manufacturing and distributing machinery and tools used in the SMT assembly process. They offer a wide range of equipment, including pick-and-place machines, soldering machines, stencil printers, reflow ovens, and inspection systems. These suppliers play a critical role in ensuring that manufacturers have access to the latest technology and equipment to meet their production needs.

2. Factors to Consider When Choosing SMT Equipment Suppliers?

a. Quality: When it comes to SMT equipment, quality is of utmost importance. Look for suppliers that have a reputation for manufacturing high-quality equipment that meets industry standards. This ensures that your production processes run smoothly and efficiently, minimizing the risk of defects and rework.

b. Reliability: The suppliers should be reliable in terms of delivering products on time and providing excellent after-sales support. Downtime in the manufacturing process can be costly, so it is essential to choose suppliers that prioritize customer satisfaction and offer prompt technical assistance when needed.

c. Technology and Innovation: The electronics manufacturing industry is constantly evolving, with new technologies and innovations emerging regularly. Choose suppliers that stay up-to-date with the latest advancements in SMT equipment. This ensures that you have access to cutting-edge technology that can enhance your production capabilities and keep you ahead of the competition.

d. Customization Options: Every manufacturing facility has unique requirements and specifications. Look for suppliers that offer customization options to tailor their equipment to your specific needs. This can include modifications to machine parameters, software integration, or even the development of entirely new equipment to meet your production demands.

3. Benefits of Working with SMT Equipment Suppliers?

a. Expertise and Technical Support: The suppliers have in-depth knowledge and expertise in the field of electronics manufacturing. They can provide valuable guidance and technical support, helping you optimize your production processes and troubleshoot any issues that may arise.

b. Cost Savings: By partnering with reputable suppliers, you can benefit from cost savings in the long run. High-quality equipment reduces the risk of defects and rework, minimizing production downtime and associated costs. Additionally, suppliers may offer competitive pricing and flexible payment options, allowing you to manage your budget effectively.

c. Access to a Wide Range of Equipment: The suppliers typically offer a diverse range of machinery and tools to cater to different manufacturing needs. This gives you the flexibility to choose equipment that aligns with your production requirements, whether you are a small-scale manufacturer or a large-scale production facility.

4. Sourcing and Wholesaling SMT Equipment?

While sourcing SMT equipment, you may come across the term “wholesale SMT equipment.” Wholesale refers to the sale of goods in large quantities at a lower price. Some SMT equipment suppliers offer wholesale options, allowing manufacturers to purchase equipment in bulk, often at discounted rates. This can be advantageous for companies looking to scale up their production or those involved in contract manufacturing.

However, it is important to note that not all SMT equipment suppliers offer wholesale options. When searching for suppliers, focus on finding reliable and reputable companies that prioritize quality and customer satisfaction. The availability of wholesale options can be discussed during the negotiation process.

Conclusion

Choosing the right SMT equipment suppliers is crucial for the success of your electronics manufacturing operations. By considering factors such as quality, reliability, technology, and customization options, you can find suppliers that meet your specific requirements. Working with reputable suppliers offers numerous benefits, including expertise and technical support, cost savings, and access to a wide range of equipment. While wholesale options may be available, prioritize the overall quality and suitability of the equipment for your production needs. With the right suppliers by your side, you can enhance your manufacturing capabilities and stay competitive in the dynamic electronics industry.