Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Overmolding: Materials and Applications

Introduction to Overmolding

Overmolding is a process that combines two or more materials to create one strong and durable part. This technique is popular in many industries because it makes products better and more attractive. In China, overmolding is growing quickly due to new technologies and high demand in different sectors.

Common Materials Used in Overmolding in China

Choosing the right materials for overmolding is important because it affects how well the final product performs, how long it lasts, and its cost. In China, several materials are commonly used:

1. Thermoplastics

Thermoplastics are popular in overmolding because they are flexible, easy to work with, and recyclable. Common thermoplastics include:

- Polypropylene (PP): Resistant to chemicals and lightweight.

- Polyethylene (PE): Tough and flexible.

- Polycarbonate (PC): Strong and clear.

These materials are great for parts that need to be both strong and flexible.

2. Thermosetting Plastics

Thermosetting plastics become hard and heat-resistant after they are processed. Examples include:

- Epoxy: Sticks well and insulates against electricity.

- Phenolic: Handles high temperatures and is very durable.

- Urea-formaldehyde: Hard and moisture-resistant.

These materials are used where heat and stress are high.

3. Elastomers

Elastomers, like Silicone Rubber, Nitrile Rubber, and EPDM, are stretchy and flexible. They provide good grip, cushioning, and resist UV light and extreme temperatures, making them suitable for flexible and durable applications.

Benefits of Different Overmolding Materials

1. Enhanced Durability and Strength

Combining different materials in overmolding makes products stronger and more durable. For example, using a hard plastic over a soft rubber can create a part that is tough but still comfortable to use.

2. Improved Aesthetic Appeal

Overmolding allows for multiple colors and textures in one part, making it look better. This is important in consumer products and electronics where appearance matters.

3. Cost Efficiency and Material Versatility

Using a combination of materials can save money and meet specific needs without using expensive single materials. Overmolding makes it possible to get the best properties from different materials.

4. Functional Benefits

Overmolding can improve grip, insulation, and shock absorption. For example, grips on tools and medical devices can be more comfortable and easier to control, while electronic parts can be better protected from heat.

Innovations in Material Technology for Overmolding

1. Advanced Composites

New materials like Carbon Fiber Reinforced Plastics (CFRP) are very strong and light. They are used in high-performance areas like automotive and aerospace parts.

2. Bio-Based Materials

There is a trend towards using eco-friendly materials made from renewable sources. These materials, like bioplastics from corn or algae, help reduce environmental impact.

3. Smart Materials and Functional Additives

New smart materials can repair themselves or conduct electricity, allowing for advanced features like sensors and actuators in overmolded parts.

Applications of Overmolding in Various Industries

1. Automotive Industry

Overmolding is used to make car parts that are durable and look good. Examples include handles and dashboard components that need to be tough and attractive.

2. Electronics Industry

In electronics, overmolding creates protective housings and connectors that are secure and resistant to environmental factors.

3. Medical Devices

Overmolding is important in making medical tools that need to be precise, durable, and hygienic. Examples include grips on surgical instruments and seals that prevent leaks.

4. Consumer Goods

Overmolding improves the functionality and look of everyday products. For example, kitchen utensils and tools with overmolded handles are easier to use and last longer.

Examples of Overmolded Products in China

1. Automotive Parts

Chinese manufacturers produce high-quality overmolded car parts like gear knobs and trim pieces that combine looks with functionality.

2. Electronic Casings

Overmolded casings for electronics in China provide strong protection and ergonomic designs.

3. Medical Device Components

China is a major producer of overmolded medical parts like surgical grips and diagnostic equipment housings that need to be precise and durable.

4. Consumer Products

Chinese manufacturers make a wide range of overmolded consumer products, such as ergonomic handles for tools and kitchen appliances.

Overmolding Techniques

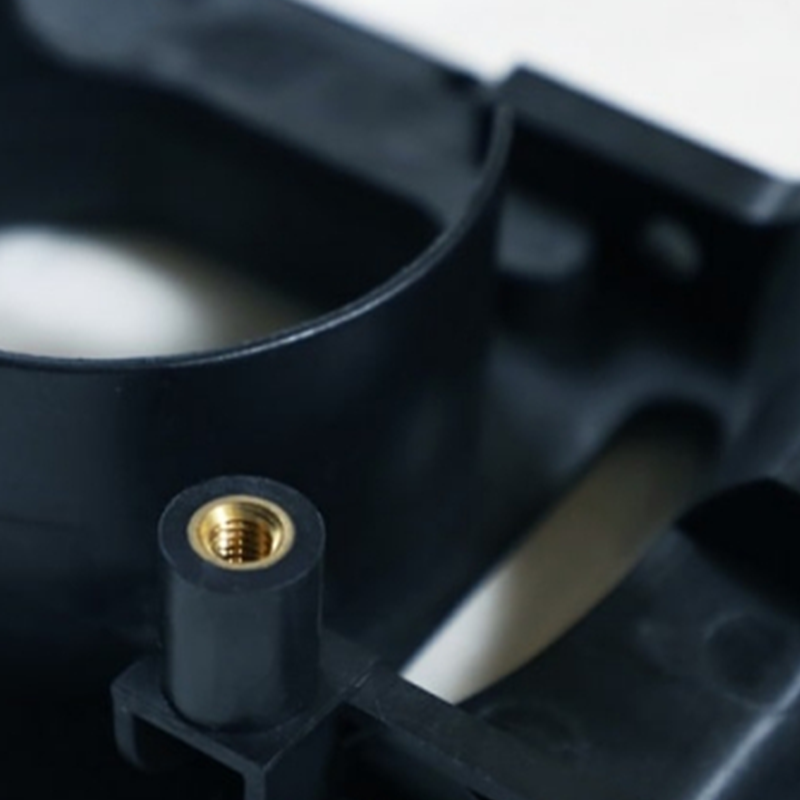

1. Insert Molding

Insert molding places pre-formed parts into a mold and then injects another material around them. This is great for combining metal parts with plastic, making strong and functional components.

2. Two-Shot Molding

Two-shot molding injects two different materials one after the other into a mold, creating parts with different properties, such as soft-touch surfaces with hard structures.

3. Multi-Shot Molding

Multi-shot molding uses more than two materials or colors in one mold cycle, producing complex and colorful parts.

Advances in Overmolding Machinery and Equipment in China

1. Automation and Robotics

Automation and robotics improve precision, efficiency, and consistency in overmolding, reducing costs and enhancing quality.

2. Advanced Molding Equipment

New machines can produce parts faster and more accurately. Multi-material machines can process different materials at once, expanding design options and efficiency.

3. Industry 4.0 Technologies

Smart sensors and real-time monitoring systems in overmolding processes allow for better decision-making, predictive maintenance, and quality control, leading to more efficient manufacturing.

Conclusion

Overmolding is a versatile manufacturing technique that continues to evolve, especially in China. The use of various materials and new technologies expands the applications of overmolding in automotive, electronics, medical devices, and consumer goods. As technology advances, the future of overmolding holds even greater potential for innovative and high-quality products.