Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Exploring the Benefits and Opportunities of an OEM CNC Plasma Cutting Service Factory

In the rapidly evolving world of manufacturing, precision and efficiency are paramount. Among the many technologies that have revolutionized the industry, CNC plasma cutting stands out for its ability to deliver high-quality cuts with remarkable speed and accuracy. For businesses looking to leverage this technology without the burden of owning and maintaining their own equipment, partnering with an OEM CNC plasma cutting service factory can be a game-changer. In this blog, we will delve into the benefits, applications, and opportunities that come with utilizing such services.

Understanding CNC Plasma Cutting

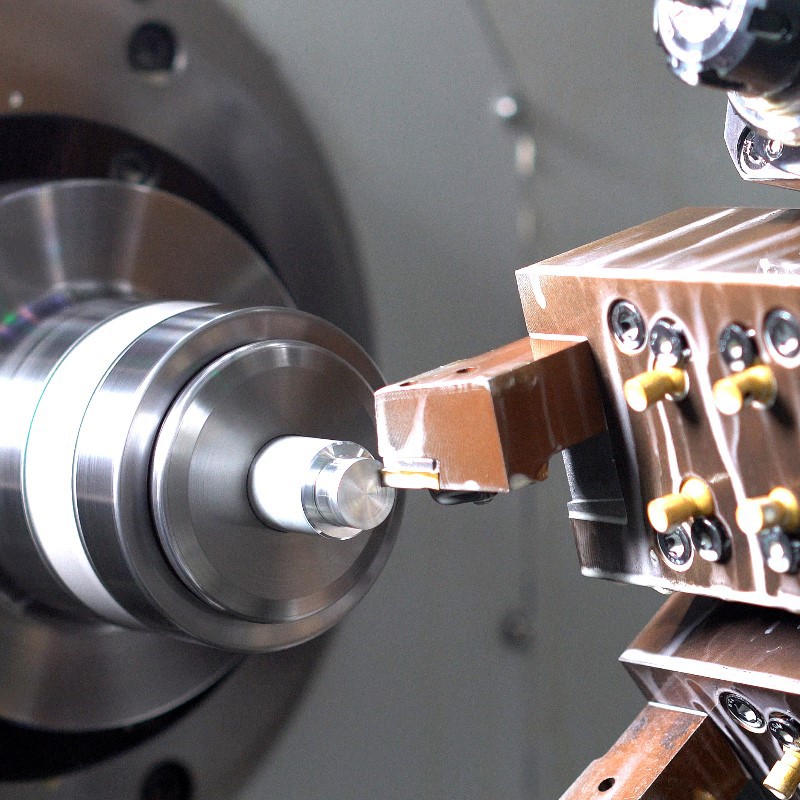

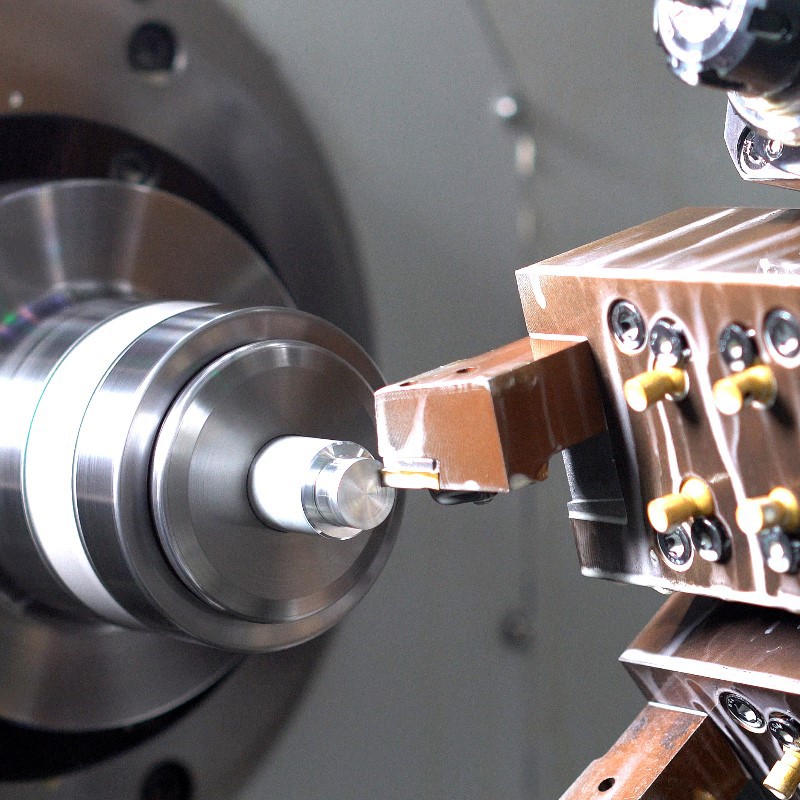

CNC (Computer Numerical Control) plasma cutting is a process that uses a high-velocity jet of ionized gas (plasma) to cut through electrically conductive materials like steel, aluminum, and copper. The precision of this method is achieved through computer control, which directs the plasma torch along a predetermined path, ensuring exact cuts every time. The process is widely appreciated for its speed, precision, and ability to cut complex shapes.

Benefits of Partnering with an OEM CNC Plasma Cutting Service Factory

1. Cost Efficiency

One of the primary advantages of using an OEM CNC plasma cutting service factory is cost efficiency. Investing in CNC plasma cutting equipment can be prohibitively expensive for many businesses, especially small to medium-sized enterprises. By outsourcing to a specialized factory, companies can avoid the significant capital expenditure and ongoing maintenance costs associated with owning such machinery. This allows businesses to allocate their resources more effectively, focusing on core activities rather than equipment management.

2. Expertise and Quality

OEM CNC plasma cutting service factories are staffed with skilled technicians who have extensive experience in operating and maintaining cutting-edge machinery. This expertise translates into superior quality cuts and reduced risk of errors. Moreover, these factories adhere to strict quality control measures, ensuring that the final products meet or exceed industry standards. For businesses, this means receiving parts and components that are consistently precise and reliable.

3. Flexibility and Scalability

Another significant advantage of partnering with an OEM CNC plasma cutting service factory is the flexibility and scalability it offers. Whether a business needs a small batch of custom parts or a large-scale production run, these factories can accommodate varying volumes without compromising on quality. This scalability is particularly beneficial for companies experiencing fluctuating demand or those looking to scale their operations without investing in additional equipment.

4. Focus on Core Competencies

Outsourcing CNC plasma cutting to a specialized factory allows businesses to concentrate on their core competencies. Instead of diverting attention and resources to managing cutting operations, companies can focus on areas like product design, marketing, and customer service. This strategic focus can lead to increased innovation, improved customer satisfaction, and overall business growth.

Applications of CNC Plasma Cutting Services

The versatility of CNC plasma cutting makes it suitable for a wide range of applications across various industries. Here are some key sectors that benefit from these services:

1. Automotive Industry

In the automotive industry, precision and durability are crucial. CNC plasma cutting is used to produce intricate parts and components with high accuracy, ensuring they fit seamlessly into vehicles. From chassis components to custom exhaust systems, the automotive sector relies heavily on the precision of CNC plasma cutting.

2. Construction and Architecture

For construction and architectural projects, CNC plasma cutting is invaluable in creating custom metal parts for structural and decorative purposes. This includes everything from steel beams and columns to intricate metal facades and artistic installations. The ability to produce detailed and complex shapes makes CNC plasma cutting an essential tool in these fields.

3. Manufacturing and Industrial Equipment

Manufacturers of industrial equipment and machinery often require custom metal parts with precise dimensions. CNC plasma cutting services provide the accuracy and consistency needed to produce high-quality components, ensuring the smooth operation of machinery and equipment.

4. Art and Design

Artists and designers also benefit from CNC plasma cutting services. The technology allows for the creation of intricate and unique metal art pieces, sculptures, and decorative elements. The precision and versatility of CNC plasma cutting enable artists to bring their creative visions to life with metal.

Opportunities in Partnering with an OEM CNC Plasma Cutting Service Factory

1. Customization and Innovation

By collaborating with an OEM CNC plasma cutting service factory, businesses can offer highly customized products to their customers. This level of customization can set a company apart from competitors and open up new market opportunities. Additionally, the ability to quickly prototype and test new designs fosters innovation, enabling businesses to stay ahead in a competitive market.

2. Enhanced Product Offerings

Partnering with a specialized factory allows businesses to expand their product offerings without significant investment in new equipment. This can be particularly advantageous for companies looking to diversify their product lines or enter new markets. The capability to produce a wide range of parts and components enhances a company’s flexibility and market responsiveness.

3. Strategic Partnerships

Building a strong relationship with an OEM CNC plasma cutting service factory can lead to strategic partnerships. These partnerships can result in collaborative innovation, shared resources, and mutual growth. For example, a manufacturer might work closely with the factory to develop new cutting techniques or materials that benefit both parties.

4. Improved Supply Chain Management

Outsourcing to a reliable CNC plasma cutting service factory can streamline supply chain management. With the factory handling production, businesses can reduce lead times, manage inventory more effectively, and respond quickly to customer demands. This improved efficiency can enhance overall supply chain performance and customer satisfaction.

Conclusion

The advantages of partnering with an OEM CNC plasma cutting service factory are manifold. From cost savings and superior quality to flexibility and enhanced product offerings, businesses can significantly benefit from outsourcing their cutting needs to specialized factories. By leveraging the expertise and capabilities of these factories, companies can focus on their core competencies, drive innovation, and achieve sustainable growth in a competitive marketplace.

Incorporating OEM CNC plasma cutting services into your business strategy can open up new opportunities and provide a competitive edge. Whether you are in the automotive, construction, manufacturing, or art and design industry, the precision, efficiency, and versatility of CNC plasma cutting can help you achieve your business goals. Embrace the future of manufacturing by partnering with an OEM CNC plasma cutting service factory and unlock the full potential of this cutting-edge technology.