Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Surface Mount Technology (SMT) has revolutionized the production process in the fast-paced world of electronics manufacturing. The efficiency and precision of the assembly line heavily rely on the crucial role played by SMT line equipment. In this post, we will explore the significance of SMT line equipment and how it enhances the overall manufacturing process.

1. Understanding SMT Line Equipment?

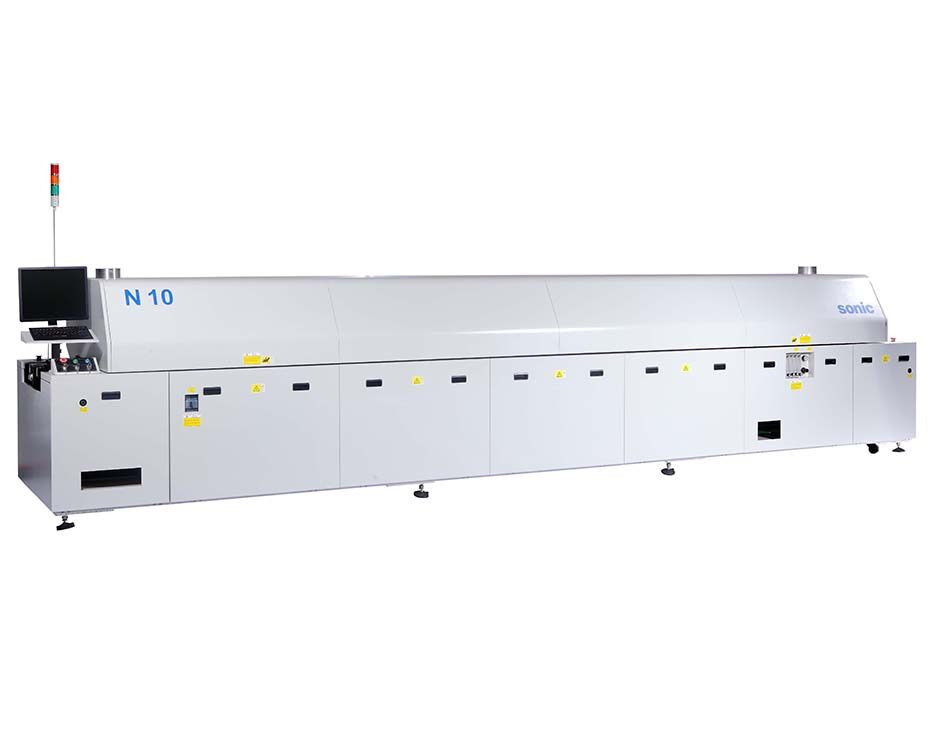

SMT line equipment refers to a range of machines and tools used in the assembly of electronic components on printed circuit boards (PCBs). These equipment include pick-and-place machines, reflow ovens, solder paste printers, inspection systems, and more. The integration of these machines into a cohesive assembly line is essential for achieving high-quality and reliable electronic products.

● The pick-and-place machines are responsible for accurately placing electronic components onto the PCBs. These machines use advanced vision systems and robotic arms to ensure precise component alignment. By automating this process, pick-and-place machines significantly reduce the time and effort required for manual component placement.

● Reflow ovens are used to solder the components onto the PCBs. These ovens heat the solder paste, causing it to melt and form a strong bond between the components and the PCB. The temperature and duration of the reflow process are carefully controlled to prevent damage to the components and ensure reliable solder joints.

● Solder paste printers, such as the MPM stencil printer, play a crucial role in the SMT assembly process. These printers accurately deposit solder paste onto the PCBs before component placement. The printer ensures precise alignment and consistent solder paste thickness, enabling reliable solder joints. Its advanced features, such as vision systems and automatic alignment, further enhance its efficiency and accuracy.

● Inspection systems are used to detect any defects or errors in the assembly process. These systems employ various techniques, such as automated optical inspection (AOI) and X-ray inspection, to identify issues such as misaligned components, solder bridging, or insufficient solder paste deposition. Early detection of defects allows for timely rework or correction, minimizing the risk of faulty products reaching the market.

2. Importance of SMT Line Equipment?

2.1 Improved Efficiency: the equipment automates the assembly process, reducing the need for manual labor and increasing production speed. The use of advanced pick-and-place machines ensures accurate component placement, minimizing errors and rework. This leads to improved efficiency and faster turnaround times.

By automating repetitive tasks, it allows operators to focus on more complex and critical aspects of the assembly process. This not only improves efficiency but also reduces operator fatigue and increases overall productivity.

2.2 Enhanced Precision: Precision is crucial in electronics manufacturing, and it plays a vital role in achieving it. The use of high-precision machines, such as the MPM stencil printer, ensures accurate solder paste deposition on PCBs. This precision results in better solder joints, reducing the risk of electrical failures and improving overall product quality.

The MPM printer, with its advanced vision systems and automatic alignment features, ensures that the solder paste is deposited precisely on the designated areas of the PCB. This eliminates the risk of misalignment or inconsistent solder paste thickness, which can lead to poor solder joints and unreliable connections.

2.3 Cost Reduction: By automating the assembly process, it helps reduce labor costs. Additionally, the use of advanced inspection systems ensures early detection of defects, minimizing the need for rework and reducing material wastage. These cost-saving benefits make it a valuable investment for electronics manufacturers.

The automation provided by SMT line equipment also reduces the risk of human error, which can lead to costly mistakes and rework. By minimizing errors and defects, manufacturers can save on both material costs and the time required for rework or product recalls.

3. Optimizing SMT Line Equipment?

3.1 Regular Maintenance: To ensure optimal performance, regular maintenance is essential. This includes cleaning, calibration, and inspection of machines to identify any potential issues. Timely maintenance helps prevent unexpected breakdowns and ensures consistent production output.

Regular cleaning of the machines helps remove dust, debris, and solder residues that can affect their performance. Calibration ensures that the machines are operating within the specified tolerances, guaranteeing accurate component placement and solder paste deposition. Inspection and testing of the machines help identify any worn-out or faulty components that may need replacement.

3.2 Upgrading Technology: As technology advances, it is crucial to keep up with the latest developments in the equipment. Upgrading to newer models or adding advanced features can significantly improve efficiency and precision. Manufacturers should stay informed about industry trends and invest in equipment that aligns with their production requirements.

Newer SMT line equipment often comes with improved automation capabilities, faster processing speeds, and enhanced precision. These advancements can help manufacturers increase production output, reduce errors, and improve overall product quality. Additionally, upgrading to more energy-efficient machines can lead to cost savings in the long run.

3.3 Training and Skill Development: Proper training and skill development of operators are vital for maximizing the potential. Operators should be well-versed in machine operation, troubleshooting, and maintenance. Regular training sessions and workshops can help enhance their knowledge and expertise, leading to improved productivity.

Training programs should cover machine operation, programming, and maintenance procedures. Operators should also be trained in identifying and resolving common issues that may arise during the assembly process. By empowering operators with the necessary skills and knowledge, manufacturers can ensure smooth operation of the SMT line equipment and minimize downtime.

Conclusion: SMT line equipment plays a crucial role in enhancing efficiency and precision in electronics manufacturing. By automating the assembly process, reducing errors, and improving solder joint quality, these machines contribute to the production of high-quality electronic products. Regular maintenance, technology upgrades, and operator training are essential for optimizing the performance. Embracing these practices will enable manufacturers to stay competitive in the dynamic world of electronics manufacturin